In today’s competitive market, packaging plays a pivotal role in product protection, branding, and logistics. One packaging method that has gained widespread adoption across various industries is heat shrink packaging. Known for its versatility, durability, and cost-effectiveness, heat shrink packaging is an essential solution for manufacturers, retailers, and distributors alike.

In this comprehensive guide, we’ll explore what heat shrink packaging is, how it works, its key benefits, and where it’s being used today. We’ll also look into technological innovations shaping its future.

What Is Heat Shrink Packaging?

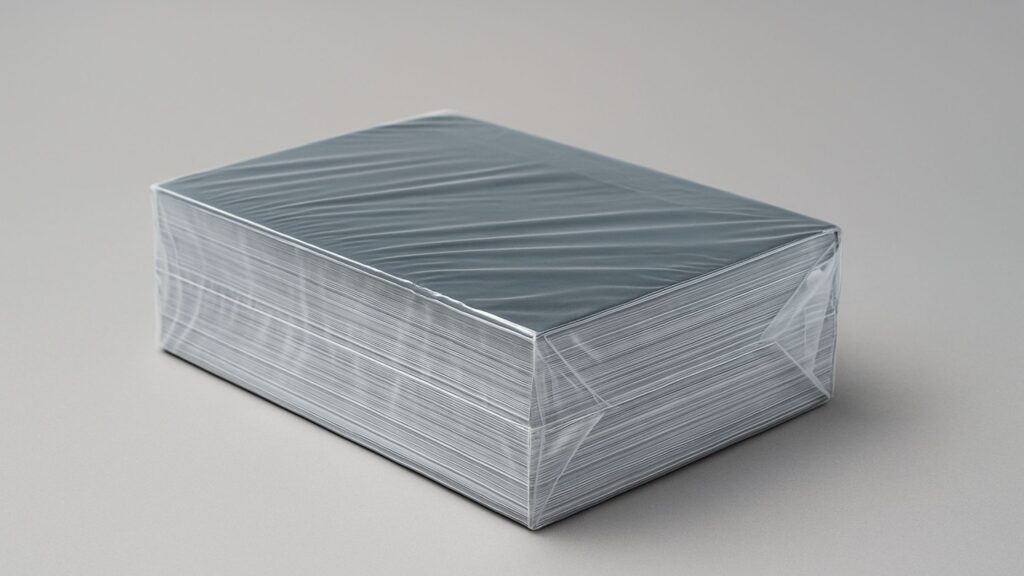

Heat shrink packaging is a packaging process that involves wrapping a product in a plastic film and then applying heat, causing the film to shrink tightly around the product. The end result is a sealed, secure package that conforms to the shape of the item, providing protection, stability, and an attractive appearance.

The plastic used is typically a polymer material such as:

-

Polyolefin

-

PVC (Polyvinyl Chloride)

-

Polyethylene

-

Polypropylene

These materials are chosen for their flexibility, clarity, and shrinkability when exposed to heat.

How Does Heat Shrink Packaging Work?

The process of heat shrink packaging generally involves the following steps:

-

Product Placement: The item is placed within a shrink film—either manually or through an automated system.

-

Sealing: The film is sealed using a heat sealer, enclosing the product completely or partially.

-

Heating: Heat is applied, usually via a heat gun or a shrink tunnel. This causes the film to contract and conform to the product’s contours.

-

Cooling: Once shrunk, the film is allowed to cool and harden, resulting in a tight, tamper-evident package.

Key Benefits of Heat Shrink Packaging

1. Enhanced Product Protection

Heat shrink packaging provides a strong barrier against dust, moisture, and other environmental contaminants. This is particularly useful for food products, electronics, and pharmaceuticals.

2. Tamper Evidence

A securely shrunk film shows visible signs if tampered with, adding an extra layer of security to sensitive or high-value goods.

3. Improved Aesthetics and Branding

Shrink films are often clear, allowing customers to view the product while still protected. The smooth, tight finish enhances shelf appeal and can be customized with labels or printed graphics.

4. Cost-Efficiency

Compared to rigid packaging, shrink wrap is lightweight and often more affordable. It also takes up less storage space, reducing warehousing and shipping costs.

5. Versatility

Heat shrink packaging is suitable for a wide range of product sizes and shapes—from single small items to large pallet loads.

6. Sustainability

Many shrink films are recyclable, and ongoing innovations are improving their environmental performance. Thinner, stronger films mean less plastic is used overall.

Common Applications of Heat Shrink Packaging

1. Food and Beverage

Shrink wrap is widely used to package bottled water, canned beverages, frozen meals, baked goods, and fresh produce. It ensures hygiene while allowing consumers to see the product.

2. Pharmaceuticals

In the healthcare sector, heat shrink packaging is used for unit-dose medications, medical devices, and tamper-evident seals.

3. Electronics

From cables and batteries to small gadgets, heat shrink protects electronics from dust and moisture and helps with organized bundling.

4. Retail and Consumer Goods

Toys, cosmetics, stationery, and DVDs are often shrink-wrapped for display, security, and storage.

5. Industrial and Automotive

Larger items like machinery parts or automotive components benefit from industrial-strength shrink wrap, which provides durability and corrosion resistance.

6. Logistics and Palletizing

Shrink wrap is commonly used to secure multiple items on a pallet, ensuring stability during shipping and storage.

Types of Shrink Films

Understanding the different types of shrink films is essential for choosing the right solution:

1. Polyolefin Shrink Film

-

Highly durable and flexible

-

FDA-approved for food contact

-

Strong seal and glossy appearance

-

Excellent for high-speed packaging lines

2. PVC Shrink Film

-

Inexpensive and easy to use

-

Good clarity

-

Not suitable for food packaging

-

Releases odors and gases when heated

3. Polyethylene Shrink Film

-

Commonly used for bundling and large-scale wrapping

-

High puncture resistance

-

Available in LDPE (Low-Density Polyethylene) for shrink bundling

-

Often used in shrink sleeves for bottles

4. Polypropylene Shrink Film

-

High clarity and low shrink rate

-

Less common than other types

-

Often used in specialty applications

Equipment Used in Heat Shrink Packaging

To apply heat shrink packaging effectively, you need the right equipment. This includes:

1. Shrink Tunnels

Automated machines that convey products through a heated chamber for consistent shrinkage.

2. Heat Guns

Handheld devices ideal for small-scale operations or spot shrinking.

3. L-Bar Sealers

These devices seal and cut the shrink film in one motion, ideal for smaller or irregularly shaped products.

4. Shrink Wrap Machines

Integrated systems that handle sealing and shrinking automatically, used in high-volume packaging lines.

Challenges and Considerations

Despite its advantages, heat shrink packaging does come with certain challenges:

-

Environmental Concerns: Although recyclable, shrink film is still plastic. Businesses must balance functionality with sustainability.

-

Initial Investment: High-end shrink wrap systems can be costly for small businesses.

-

Heat Sensitivity: Not all products can tolerate the heat involved in the process.

Innovations in Heat Shrink Packaging

As consumer and regulatory pressures for sustainable packaging grow, the heat shrink industry is evolving:

1. Biodegradable and Compostable Films

New film technologies are emerging that break down more quickly in the environment, reducing long-term waste.

2. Recyclable Multi-Layer Films

Advanced films are being engineered to offer the strength of multi-layer compositions while remaining compatible with standard recycling systems.

3. Reduced-Gauge Films

Thinner yet stronger shrink films are now available, using less plastic while maintaining durability and performance.

4. Automation and Smart Packaging

Modern shrink packaging systems incorporate AI and IoT for quality control, predictive maintenance, and integration with logistics software.

Heat Shrink Packaging vs. Stretch Wrap: What’s the Difference?

These two terms are often confused, but they serve different purposes:

| Feature | Heat Shrink Packaging | Stretch Wrap |

|---|---|---|

| Application | Uses heat to shrink film tightly | Stretched around items manually or mechanically |

| Use Case | Retail packaging, food, electronics | Palletizing and bundling shipments |

| Equipment Needed | Shrink tunnel, sealer, or heat gun | Stretch wrap dispenser or machine |

| Cost | Moderate to High | Low to Moderate |

| Appearance | Sleek, professional finish | Functional, less visually appealing |

Best Practices for Using Heat Shrink Packaging

If you’re considering implementing heat shrink packaging, here are some key tips:

-

Select the Right Film: Match your film type to your product and desired appearance.

-

Use Quality Equipment: Investing in reliable heat tunnels and sealers ensures consistency.

-

Train Your Staff: Proper training minimizes waste and improves package quality.

-

Monitor Temperature Settings: Overheating can damage products or the film; underheating results in poor seals.

-

Regular Maintenance: Keep your equipment in top shape for maximum efficiency.

Conclusion

Heat shrink packaging has proven itself to be a reliable, efficient, and adaptable packaging solution across countless industries. Its ability to enhance product appeal, improve shelf life, and reduce logistical complications makes it a favorite for both manufacturers and consumers.

As technology advances and sustainability becomes more critical, we can expect further innovations that make heat shrink packaging even more appealing. Whether you’re a small business or a large manufacturer, understanding how to leverage heat shrink packaging can give you a significant competitive advantage.

Final Thoughts

If you’re looking to streamline your packaging operations, improve product presentation, or enhance shipping durability, heat shrink packaging deserves your consideration. With its combination of practicality, protection, and presentation, it continues to set the standard in modern packaging.

Interested in integrating heat shrink packaging into your workflow?

Contact a packaging specialist today or explore automated systems that can elevate your production line.

Related Articles

- Understanding Primary Secondary Tertiary Packaging: A Comprehensive Guide

- Primary Packaging in Pharmaceutical Industry: Types, Importance, and Trends

- Secondary Packaging Solutions: Optimizing Your Supply Chain and Product Presentation

- Secondary Packaging of Toothpaste: Everything You Need to Know

- Secondary Packaging of Tea: Materials, Types & Trends Explained

- Secondary Packaging of Shoes: Function, Innovation, and Sustainability

- Secondary Packaging of Shampoo: Purpose, Materials, and Innovations

- Secondary Packaging of Perfume: Purpose, Innovation, and Impact

- Secondary Packaging of Lipstick: Balancing Beauty, Protection, and Sustainability

- Secondary Packaging of Coffee: Complete Guide for Coffee Brands

- Secondary Packaging of Chocolate: The Unsung Hero Behind Every Sweet Success