In the ever-evolving world of packaging, efficiency, accuracy, and compliance are the cornerstones of success. Whether you’re operating in food, pharmaceuticals, cosmetics, or manufacturing, the precision of every product that leaves your line directly impacts your brand’s credibility and customer satisfaction. One technological advancement leading this transformation is the auto checkweigher machine.

At The Packaging Edge, we understand that packaging is no longer just about containment or aesthetics; it’s about performance, safety, and compliance. In this comprehensive blog, we’ll explore the importance of auto checkweigher machines, their benefits, applications, and why they are becoming an essential investment for modern businesses.

What is an Auto Checkweigher Machine?

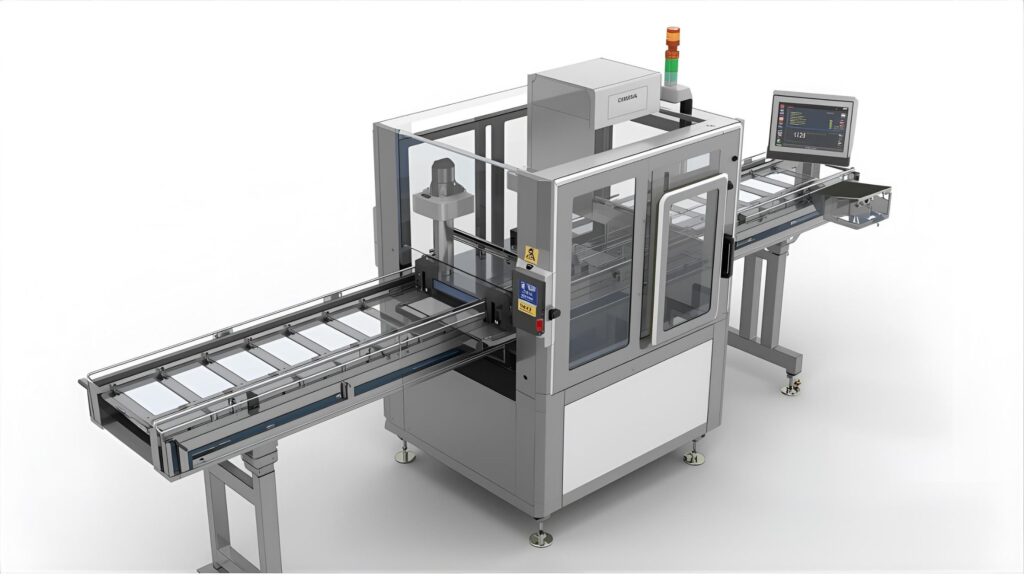

An auto checkweigher machine is an automated device that ensures every packaged product meets the specified weight standards. As products move along the conveyor belt, the machine automatically weighs them in motion without interrupting production. If a package is overweight or underweight, the system identifies and rejects it in real-time.

This seemingly small process plays a massive role in safeguarding quality, ensuring compliance with industry standards, and maintaining consumer trust. Unlike manual weighing, auto checkweighers provide unmatched speed, consistency, and reliability.

Why Accuracy Matters in Packaging

A single underweight package can lead to consumer dissatisfaction, product recalls, or even penalties for non-compliance. On the other hand, consistently overweight products increase production costs and erode profitability. Auto checkweighers act as guardians of accuracy, bridging the gap between efficiency and compliance.

- Regulatory Compliance: Many industries have strict weight compliance standards (e.g., food safety authorities, pharmaceutical guidelines). Auto checkweighers help companies avoid fines and reputational damage.

- Customer Trust: A reliable product weight builds confidence in consumers, enhancing brand loyalty.

- Cost Efficiency: By reducing overfills, businesses can save significant amounts in raw materials and maximize profit margins.

Benefits of an Auto Checkweigher Machine

- Enhanced Quality Control

Every product that passes through an auto checkweigher is verified for accuracy. This eliminates the risk of substandard products reaching the market. - Reduced Product Wastage

Overfilling wastes valuable resources. By minimizing this, checkweighers increase sustainability and profitability. - Improved Production Efficiency

Unlike manual inspections, which are slow and prone to human error, auto checkweighers integrate seamlessly into production lines, maintaining high throughput without interruptions. - Real-Time Monitoring

Modern machines come with digital interfaces that allow real-time data analysis, enabling proactive decision-making and quick troubleshooting. - Customizable Applications

From small pouches to large cartons, auto checkweighers can be customized to suit different product categories and packaging lines. - Return on Investment (ROI)

While the upfront cost might seem high, businesses often recover their investment quickly through reduced wastage, compliance protection, and increased efficiency.

Key Industries Using Auto Checkweigher Machines

- Food & Beverage Industry

Compliance with health and safety standards makes auto checkweighers a necessity in food packaging. They ensure every snack, beverage, or processed item meets legal weight requirements. - Pharmaceutical Industry

In pharmaceuticals, precision is non-negotiable. Auto checkweighers ensure blister packs, bottles, and sachets meet strict dosage accuracy. - Cosmetics Industry

From creams to perfumes, maintaining consistency in packaging weight enhances both brand perception and consumer satisfaction. - Logistics & Manufacturing

Beyond consumables, industries like logistics rely on weight accuracy for inventory management, shipping costs, and compliance.

How Auto Checkweigher Machines Work

- Product Entry

The product enters the conveyor system. - Dynamic Weighing

The integrated load cell measures the weight while the product is in motion. - Data Analysis

The system compares the actual weight with pre-set parameters. - Sorting

If a product doesn’t meet the standard, the machine rejects it using a pusher, air blast, or diverter.

This process happens seamlessly, often in milliseconds, ensuring no compromise on production speed.

Features to Look for in an Auto Checkweigher Machine

When choosing the right machine for your production line, consider:

- Accuracy Range: Ensure it meets your industry’s tolerance levels.

- Speed Compatibility: It should match the pace of your production line.

- Data Integration: Opt for models with connectivity for real-time reporting.

- Custom Design Options: Machines that adapt to your product size, shape, and packaging style.

- Durability & Hygiene: Especially important for industries like food and pharma.

Future Trends in Auto Checkweigher Machines

The evolution of technology is reshaping the capabilities of checkweighers:

- AI & Machine Learning Integration: Predictive analytics will allow machines to self-optimize based on production trends.

- IoT-Enabled Systems: Remote monitoring and cloud-based data storage will become standard.

- Eco-Friendly Design: Energy-efficient models will support sustainability goals.

- Compact & Modular Systems: Designed for businesses with limited floor space but high output needs.

Why Choose The Packaging Edge for Auto Checkweigher Solutions?

At The Packaging Edge, we don’t just provide packaging equipment; we deliver solutions. Our expertise ensures you get an auto checkweigher machine that fits seamlessly into your operations and elevates your packaging standards.

- Tailored Solutions: Every business is unique, and we customize our machines accordingly.

- Cutting-Edge Technology: We stay ahead of trends to provide future-ready solutions.

- Expert Consultation: Our team guides you through every step of selection, installation, and after-sales support.

- Long-Term Value: Our machines are built to last, ensuring you maximize ROI.

Final Thoughts

In today’s competitive marketplace, accuracy isn’t just an advantage—it’s a necessity. An auto checkweigher machine is more than equipment; it’s a strategic investment that guarantees compliance, boosts efficiency, and enhances consumer trust. Whether you’re in food, pharmaceuticals, or beyond, incorporating an auto checkweigher is a step toward sustainable success.

At The Packaging Edge, we are committed to helping businesses like yours achieve packaging excellence through innovative, reliable, and efficient solutions.

Are you ready to take your packaging operations to the next level? Discover how an auto checkweigher machine can revolutionize your production line today.

Reach out to us at thepackagingedge@gmail.com and let’s design the perfect solution for your business.

Related Articles

- Automatic Checkweigher Machine | Boost Packaging Efficiency

- In Motion Checkweigher: The Game-Changer in Packaging Efficiency

- Industrial Checkweigher Solutions for Packaging & Manufacturing | The Packaging Edge

- In Line Checkweigher: The Ultimate Guide to Packaging Precision | The Packaging Edge

- Automatic Checkweigher Market: Driving Accuracy and Efficiency in Packaging

- Automatic Bottle Shrink Wrap Machine – The Packaging Edge

- High Speed Checkweigher: The Key to Accuracy, Efficiency, and Compliance in Modern Packaging

- Box Lifter: Revolutionizing Material Handling with The Packaging Edge

- Crate Lifter: The Essential Tool for Modern Packaging and Logistics

- Bucket Elevator Solutions for Material Handling