In today’s fast-paced, highly competitive manufacturing and distribution environment, companies are under constant pressure to increase productivity, reduce operational costs, and deliver consistent quality. One of the most effective ways to achieve all three is by incorporating automation into the packaging line. Among the many innovations transforming modern packaging facilities, the automatic carton packing machine stands out as a powerhouse of efficiency and reliability.

Whether you operate in food and beverage, pharmaceuticals, electronics, cosmetics, FMCG, or industrial products, an automatic carton packing machine can dramatically optimize your end-of-line operations. At The Packaging Edge, we help businesses discover intelligent automation solutions that streamline workflows, boost production rates, and enhance overall packaging precision.

This comprehensive guide explores everything you need to know about automatic carton packing machines—how they work, why they offer unmatched advantages, and how choosing the right machine can accelerate your company’s growth.

What Is an Automatic Carton Packing Machine?

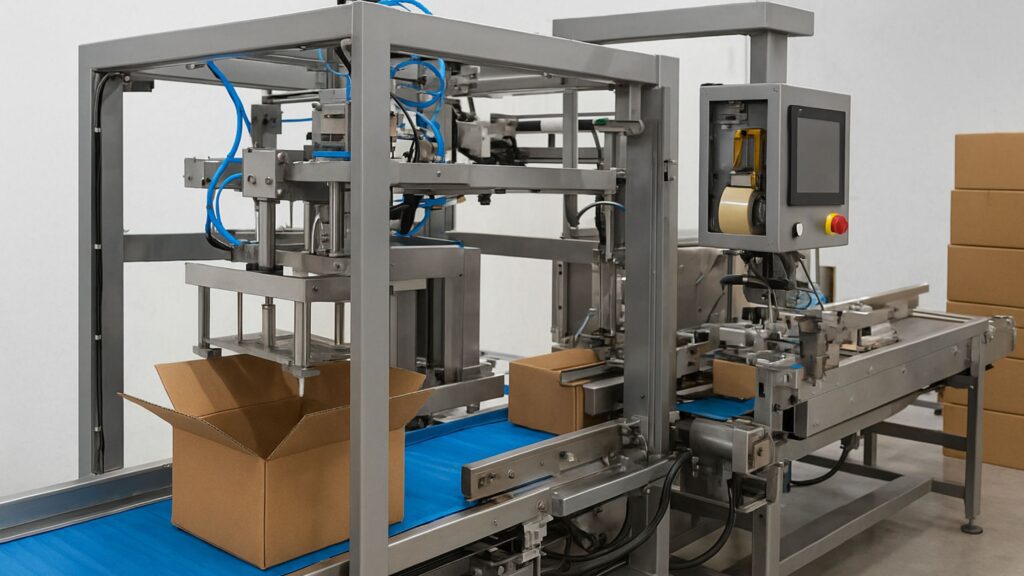

An automatic carton packing machine is a highly engineered piece of equipment designed to form, fill, and seal cartons without the need for manual intervention. Traditionally, carton packing required several steps—erecting flat cartons, inserting products, adding protective materials, folding flaps, gluing or taping, labeling, and stacking. Today, all these processes can be seamlessly automated.

Depending on the model and configuration, an automatic carton packing machine can:

-

Automatically erect the carton from a flat sheet

-

Load products into the carton with precision

-

Insert leaflets, protective padding, and accessories

-

Seal cartons using tape, glue, or other methods

-

Print or apply labels

-

Sort, stack, and prepare cartons for shipment

The result? Faster production, reduced labor costs, fewer errors, and consistent packaging quality in every batch.

Why Manufacturers Are Switching to Automatic Carton Packing Machines

Businesses across industries are rapidly transitioning to automation. But what makes the automatic carton packing machine such a compelling investment?

Below are the most impactful reasons:

1. Unmatched Speed and Efficiency

Human workers can only pack a certain number of cartons per hour—and fatigue leads to declining performance. In contrast, an automatic carton packing machine delivers:

-

Continuous high-speed operation

-

Consistent performance 24/7

-

Faster fulfillment and reduced lead times

A well-calibrated system can pack hundreds to thousands of units per hour, depending on the machine type and product.

2. Reduced Labor Costs

Labor shortages, rising wages, and high turnover have made manual packaging increasingly expensive. Automation helps businesses:

-

Minimize reliance on manual labor

-

Reduce training time

-

Avoid human error and injury-related downtime

Employees can be reallocated to higher-value tasks, improving overall operational efficiency.

3. Superior Accuracy and Precision

Automatic machines ensure consistent:

-

Carton dimensions

-

Filling volume

-

Sealing strength

-

Label positioning

-

Product orientation

This uniformity reduces rework and enhances brand image.

4. Improved Product Safety and Hygiene

For industries such as pharmaceuticals, cosmetics, and food, maintaining a hygienic packaging environment is critical. Automatic carton packing machines minimize human contact with the product, reducing contamination risks and improving regulatory compliance.

5. Space Optimization

Modern machines are designed with compact footprints. They integrate multiple packing functions into one efficient unit, helping businesses maximize their available floor space.

6. Long-Term Cost Savings

While an automatic carton packing machine requires an initial investment, the long-term benefits far outweigh the cost. Companies save on:

-

Labor

-

Material waste

-

Operational downtime

-

Maintenance

Over time, the machine pays for itself—often faster than expected.

Types of Automatic Carton Packing Machines

Understanding the different types helps you decide which solution best fits your production line.

1. Carton Erecting Machines

These machines transform flat cardboard sheets into fully formed cartons. They are essential for high-volume packaging lines.

Key Features:

-

High-speed carton forming

-

Precise creasing and corner sealing

-

Glue or tape application options

2. Carton Filling Machines

Designed to place products into cartons automatically. They support various loading mechanisms:

-

Vertical loading

-

Horizontal loading

-

Pick-and-place loading

Commonly used in food, pharmaceuticals, and cosmetics.

3. Carton Sealing Machines

After filling, cartons must be securely sealed. These machines handle:

-

Flap folding

-

Hot-melt gluing

-

Taping

-

Strapping

4. Wrap-Around Carton Packers

Ideal for products like bottles, cans, cartons, and jars. They use a flat blank that wraps around the product cluster—perfect for beverage and FMCG applications.

5. End-Load Cartoning Machines

These machines load products from the side, making them ideal for pouches, sachets, tubes, and blister packs.

6. Top-Load Cartoning Machines

Best for rigid containers, pots, or jars that require vertical placement.

7. Robotic Carton Packers

Robots add flexibility and intelligence to the process. They can:

-

Handle multiple product SKUs

-

Make quick adjustments between batches

-

Reduce downtime

-

Improve product handling precision

Industries That Benefit from Automatic Carton Packing Machines

An automatic carton packing machine brings value to any industry where products need consistent and reliable packaging. Major sectors include:

1. Food and Beverage

Perfect for:

-

Snacks

-

Cereals

-

Dairy products

-

Beverages

-

Ready-to-eat meals

Ensures hygiene and speed.

2. Pharmaceuticals

Accuracy and compliance are critical. These machines ensure:

-

Precise leaflet insertion

-

Tamper-proof packaging

-

Batch coding

3. Cosmetics and Personal Care

Ideal for:

-

Cream tubes

-

Perfume bottles

-

Cosmetic boxes

-

Sachets and kits

4. Electronics

Protects delicate products during packing.

5. Hardware and Industrial Products

Improves durability, stacking strength, and safety.

6. E-commerce & Logistics

Allows rapid and consistent packing of varied SKUs.

How an Automatic Carton Packing Machine Works (Step-by-Step Process)

While the exact operation varies based on the machine type, most systems follow these core steps:

Step 1: Carton Feeding and Erecting

Flat cartons are fed into the machine and erected automatically.

Step 2: Product Loading

Products are inserted into cartons using:

-

Conveyor systems

-

Pick-and-place robots

-

Mechanical feeders

Step 3: Leaflet/Accessory Insertion

Necessary documents or add-ons are included.

Step 4: Carton Sealing

The machine seals flaps using glue or tape.

Step 5: Coding & Labeling

Barcodes, expiry dates, or QR codes are printed or applied.

Step 6: Final Output & Stacking

Completed cartons are ejected, sorted, and prepared for shipment.

Top Features to Look for When Choosing an Automatic Carton Packing Machine

To ensure peak performance and ROI, consider these key features:

1. Speed and Capacity

Match machine speed with your production requirements.

2. Flexibility

Choose machines that can handle multiple carton sizes and formats.

3. Ease of Changeover

Quick adjustments reduce downtime between batches.

4. Compatibility with Existing Lines

Ensure seamless integration with conveyors, coding systems, and other automation.

5. Safety Features

Look for emergency stops, sensors, and protective housing.

6. Durability and Build Quality

Heavy-duty frames and premium components improve machine life.

7. Smart Controls

Modern machines offer:

-

Touchscreen interfaces

-

IoT connectivity

-

Real-time diagnostics

-

Production reporting

8. Energy Efficiency

Lower energy consumption reduces operating costs.

The Packaging Edge Advantage

At The Packaging Edge, we’re committed to helping businesses transform their packaging operations with the right automation solutions. When you partner with us, you gain:

-

Expert consultation on selecting the best machine

-

Customized machine configurations

-

High-precision engineering

-

On-site installation and training

-

Reliable after-sales service

-

Competitive pricing

We work closely with manufacturers to deliver systems that match your exact requirements—whether you need a fully automated line or a semi-automatic solution to begin your automation journey.

Benefits of Automating Your Carton Packaging Today

When you invest in an automatic carton packing machine, your business immediately benefits from:

- Faster Production

- Better Quality Control

- Reduced Downtime

- Lower Operational Costs

- Enhanced Workplace Safety

- Increased Scalability

- Stronger Brand Reputation

- Higher Profit Margins

The future of packaging is automation—and early adopters consistently achieve a competitive edge.

Common Mistakes to Avoid When Investing in an Automatic Carton Packing Machine

To protect your investment, avoid the following:

Mistake 1: Choosing Speed Over Compatibility

Speed is important, but the machine must be compatible with your products and existing workflow.

Mistake 2: Ignoring Maintenance Requirements

Preventive maintenance ensures long machine life.

Mistake 3: Underestimating Future Growth

Choose a machine that can scale with your business.

Mistake 4: Overlooking Safety Standards

Always prioritize certified machines with strong safety mechanisms.

Frequently Asked Questions

1. What products can an automatic carton packing machine handle?

Everything from bottles, jars, tubes, pouches, blister packs, and snacks to electronics, pharmaceuticals, and household items.

2. How much does an automatic carton packing machine cost?

Costs vary depending on speed, automation level, and customization. Contact us for a tailored quotation.

3. Does it require specialized operators?

Not necessarily—most modern machines feature intuitive touchscreen controls.

4. Can it handle multiple carton sizes?

Yes, with adjustable components or servo-driven configurations.

5. How long does installation take?

Typically between a few days to a few weeks, depending on the complexity of the line.

Ready to Transform Your Packaging Efficiency?

If you’re ready to streamline your operations, improve output, and enhance packaging quality, an automatic carton packing machine is the solution you need.

At The Packaging Edge, we help businesses upgrade with advanced, affordable, and reliable automation technology.

For pricing, consultation, or more details, email us at: thepackagingedge@gmail.com

Our specialists are ready to guide you step-by-step—whether you’re scaling your production or starting your automation journey.

Final Thoughts

The packaging industry is evolving rapidly, and companies that embrace automation now will outperform their competitors in the years to come. An automatic carton packing machine is more than just a piece of equipment—it’s an investment in speed, precision, and long-term profitability.

If you want to reduce labor dependency, minimize errors, and achieve consistent packaging quality, now is the perfect time to make the switch. Let The Packaging Edge help you stay ahead with intelligent, reliable, and future-ready packaging automation solutions.

Have Questions or Need a Quote?

Email us anytime at thepackagingedge@gmail.com

We’re here to help you achieve the packaging excellence your business deserves.

Related Articles

- Case Packer Machine Solutions for Modern Packaging Lines

- Food Shrink Wrap Machine: The Ultimate Guide to Boosting Shelf Life, Hygiene & Branding

- Cookie Packaging Machine: The Complete Guide for Bakeries & Food Brands

- Candy Wrapping Machine: The Complete Guide to Efficiency, Quality & Growth

- Pallet Stretch Wrap Machine | Secure & Efficient Wrapping

- Bottle Packing Machine: The Ultimate Guide to Efficiency, Speed & Precision

- Commercial Shrink Wrap Machine: The Ultimate Guide to Choosing the Best Equipment for Your Business

- Liquid Packing Machine | High-Performance Packaging Solutions

- Chips Packing Machine | High-Speed Snacks Packaging Solutions

- Industrial Vacuum Sealer Machine – The Ultimate Guide by The Packaging Edge