In today’s fast-paced manufacturing environment, the efficiency and precision of packaging processes have become more crucial than ever. Among the myriad of packaging technologies, blister packaging machines stand out as a highly versatile and efficient solution. These machines are widely used in industries like pharmaceuticals, consumer goods, food, and electronics, offering an optimal combination of product protection, tamper evidence, and visual appeal.

Whether you’re a business owner exploring packaging solutions or a production manager seeking to enhance operations, understanding blister packaging machines is essential. In this comprehensive guide, we’ll explore what blister packaging machines are, how they work, the various types, their advantages, industry applications, factors to consider when choosing one, and the future of blister packaging technology.

What Are Blister Packaging Machines?

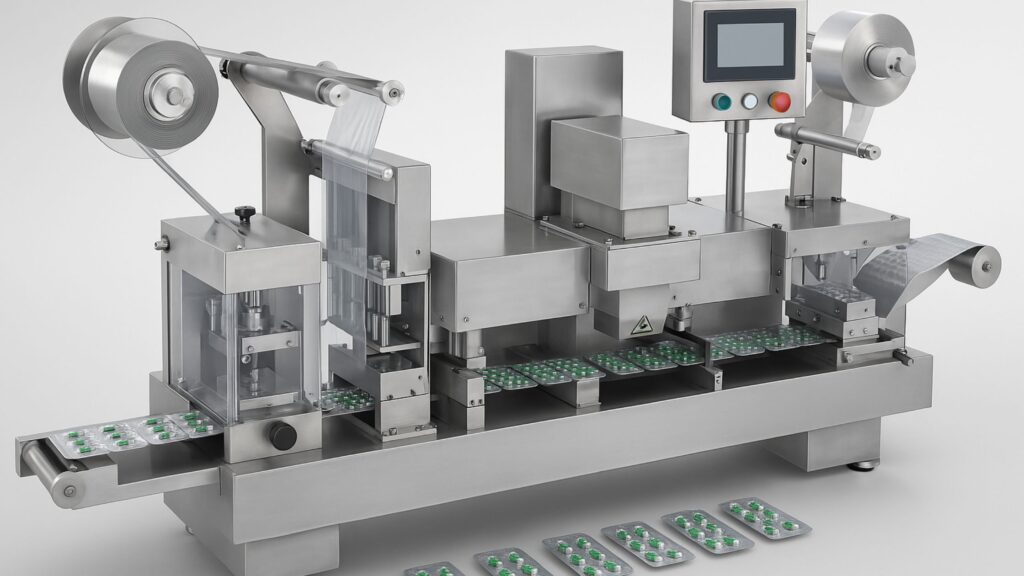

Blister packaging machines are specialized equipment designed to form blisters—small cavities or pockets—on a formable web material, typically plastic, and seal them with a backing material such as aluminum foil or paperboard. These machines automate the packaging of products in blister packs, which are commonly used for unit-dose pharmaceutical tablets and capsules, as well as various consumer and industrial products.

Blister packs serve multiple purposes:

-

Protection from moisture, contamination, and physical damage

-

Tamper evidence for safety and security

-

Convenient visibility of the product

-

Improved shelf life

How Do Blister Packaging Machines Work?

The process involves several stages:

1. Forming the Blister

-

Thermoforming: A plastic film is heated until pliable and then formed into a mold using vacuum and pressure.

-

Cold forming: Typically used for pharmaceutical applications requiring high protection; a laminate (aluminum-based) is pressed into a mold to form cavities without heat.

2. Filling

Once the blisters are formed, products are automatically or semi-automatically placed into each cavity. For instance, tablets are precisely dropped into each pocket using a feeding mechanism.

3. Sealing

A lidding material, often aluminum foil with a heat-seal coating, is applied to seal the blister. The sealing ensures the product is protected from external elements.

4. Cutting

The sealed material is then cut into individual blister packs or larger strips, depending on packaging requirements.

5. Discharge

Finished packs are ejected from the machine and directed to downstream packaging stations or packed into cartons for distribution.

Types of Blister Packaging Machines

There are various types of blister packaging machines, categorized based on automation, forming method, and application:

1. Thermoforming Blister Packaging Machines

These are the most common type. They use heat to form plastic blisters and are suited for packaging products like pills, toys, batteries, and hardware.

2. Cold Forming Blister Packaging Machines

Used primarily in the pharmaceutical sector, cold forming is suitable for moisture-sensitive products, as it provides a complete barrier to light, oxygen, and moisture.

3. Semi-Automatic Blister Packaging Machines

Ideal for small to medium-scale production. These machines require some manual operation, offering more flexibility but lower throughput.

4. Fully Automatic Blister Packaging Machines

These are high-speed machines integrated into large production lines, capable of producing thousands of blister packs per hour. They are designed for efficiency, consistency, and minimal human intervention.

5. Custom Blister Packaging Machines

Some industries require tailored blister packaging solutions. Custom machines can be designed to accommodate unique product shapes, specialized materials, or non-standard pack sizes.

Advantages of Blister Packaging Machines

1. Product Protection

Blister packs shield products from environmental contaminants such as moisture, dust, and UV light.

2. Tamper Evidence

Blister packaging provides clear indicators of tampering, enhancing product security.

3. Portion Control

Especially useful in pharmaceuticals, blister packs allow unit-dose packaging, improving dosage accuracy and compliance.

4. Branding and Visibility

Transparent blisters allow customers to see the product, while printed foil backings can include branding, instructions, and compliance details.

5. Reduced Material Waste

Compared to traditional packaging, blister packs often use less material and are easier to recycle when designed properly.

6. Increased Production Efficiency

Automated blister packaging machines reduce labor costs and increase output, making them cost-effective over time.

Applications of Blister Packaging Machines

Blister packaging machines are used across multiple industries. Let’s look at how different sectors leverage this technology:

1. Pharmaceuticals

-

Unit-dose packaging for tablets and capsules

-

Compliance packs with printed dosage instructions

-

Child-resistant and senior-friendly packs

2. Consumer Electronics

-

Packaging of USB drives, earbuds, and batteries

-

Tamper-evident seals for security

-

Transparent display to showcase design

3. Food Industry

-

Candies, gum, and individual snacks

-

Extended shelf life and freshness retention

4. Cosmetics

-

Samples of creams and lotions

-

Small quantities for trial packs

5. Industrial Products

-

Packaging for screws, bolts, and small parts

-

Easy visibility and sorting

Key Components of Blister Packaging Machines

Understanding the anatomy of a blister packaging machine can help in maintenance and troubleshooting. The main components include:

-

Forming Station: Where the plastic is shaped into blisters

-

Feeding Mechanism: Dispenses products into the cavities

-

Sealing Station: Applies heat and pressure to seal the foil

-

Cutting Unit: Cuts the packs to the desired size

-

Control Panel: Interface for setting and monitoring machine parameters

-

Conveyor and Ejector: Transports the material and ejects finished packs

Modern machines also come with advanced features like:

-

Servo motors for precision control

-

Vision inspection systems for quality assurance

-

Remote monitoring and diagnostics

Factors to Consider When Choosing a Blister Packaging Machine

Investing in the right machine is crucial. Consider the following factors:

1. Production Volume

High-speed automatic machines are ideal for large-scale production, while semi-automatic options suit smaller operations.

2. Product Type

Fragile, moisture-sensitive, or irregular-shaped items may require specific types of machines or materials.

3. Blister Material

Thermoforming is suitable for standard products, while cold forming is better for high-barrier applications.

4. Footprint and Integration

Evaluate how the machine fits into your existing production line and facility layout.

5. Regulatory Compliance

In pharmaceuticals, machines must comply with GMP (Good Manufacturing Practices), FDA, and other local regulations.

6. After-Sales Support

Reliable customer service, availability of spare parts, and training are essential for long-term operation.

Future Trends in Blister Packaging Machines

As technology evolves, so do blister packaging machines. Here are some trends to watch:

1. Smart Packaging Integration

Incorporating QR codes, NFC tags, and sensors to add digital interactivity and traceability.

2. Sustainability Initiatives

Use of recyclable materials and machines designed for lower energy consumption.

3. Modular Machine Design

Machines with modular parts for easy upgrades and flexible production capabilities.

4. AI and Automation

Enhanced machine learning algorithms for predictive maintenance, fault detection, and adaptive control systems.

5. IoT Connectivity

Real-time monitoring of performance and diagnostics through cloud-based platforms.

Conclusion

Blister packaging machines play a pivotal role in modern packaging solutions. From pharmaceuticals to electronics, their benefits are undeniable—offering superior product protection, cost-efficiency, and consumer convenience. As the packaging industry continues to innovate, investing in the right blister packaging technology will be a strategic advantage for any manufacturer.

Whether you’re scaling up your production line or entering a new market, understanding the capabilities and options of blister packaging machines can help you make an informed decision that aligns with your operational goals.

Have questions about choosing the right blister packaging machine for your business? Feel free to drop them in the comments or contact us for a consultation!

Related Articles

- Heat Seal Machines: How They Work, Types, Applications, and Buying Tips

- Everything You Need to Know About Cartoning Machines

- Pouch Filling Machines: Types, Benefits, and Industry Applications

- Everything You Need to Know About Coffee Packaging Machines

- The Future of Efficiency: Exploring the World of Automatic Packing Machines

- Blister Packing Machines: How They Work, Types, Benefits, and Industry Applications

- Flow Wrap Machines: How They Work, Benefits, and Why Your Business Needs One

- Pouch Packing Machines: Types, Benefits, and Buying Tips

- The Evolution and Importance of Food Packaging Machines in Modern Industry

- Vacuum Packaging Machines: What They Are, How They Work, and Why You Need One