In the world of material handling and packaging, efficiency, reliability, and safety are paramount. Among the many tools and machines designed to streamline operations in industries like agriculture, food processing, pharmaceuticals, and manufacturing, one stands out for its incredible versatility and effectiveness—the Bucket Elevator. At The Packaging Edge, we specialize in helping businesses optimize their operations with cutting-edge packaging and material handling solutions. Today, we dive deep into the world of bucket elevators, their uses, benefits, types, and why they are a must-have for businesses aiming for operational excellence.

What is a Bucket Elevator?

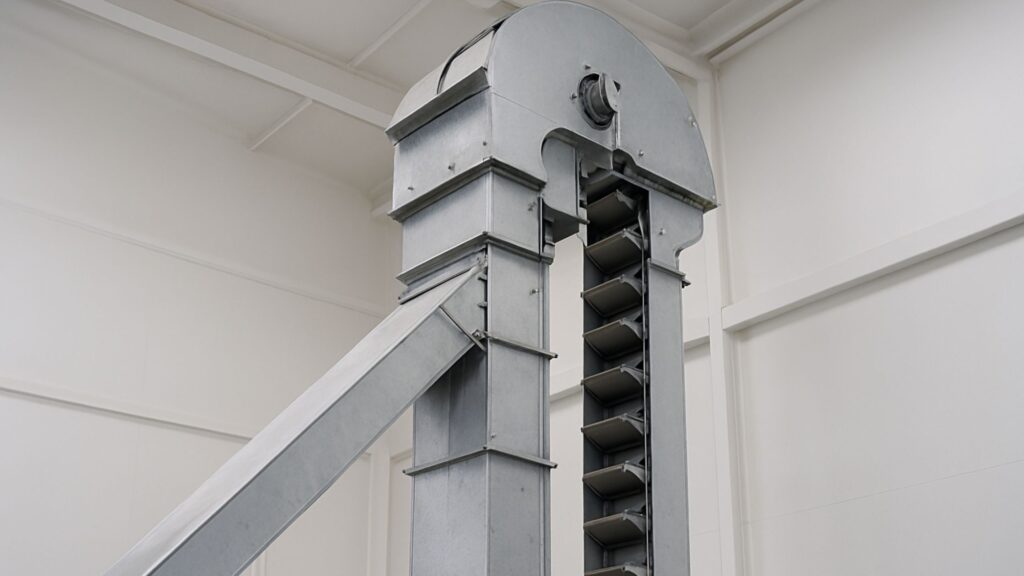

A bucket elevator is a mechanical device used to transport bulk materials vertically. It consists of a series of buckets attached to a belt or chain that moves around pulleys or sprockets. As the buckets scoop material from the bottom and carry it to the top, they discharge it into a designated chute. This simple yet effective mechanism allows industries to move materials like grains, seeds, powders, minerals, and chemicals with precision and minimal effort.

Whether it’s loading raw materials into silos, moving ingredients in food production, or transferring powders in pharmaceutical plants, elevators are essential for safe and efficient bulk material handling.

The Importance of Bucket Elevators in Modern Industries

In today’s competitive industrial environment, speed and accuracy can make or break a business. A bucket elevator is not just a tool but an investment that ensures:

- Time-saving operations: By moving materials quickly, bucket elevators cut down manual labor and improve overall productivity.

- Reduced product loss: Their design minimizes spillage, ensuring maximum material recovery.

- Consistent quality control: Precise handling prevents contamination and damage to delicate materials.

- Enhanced workplace safety: Automated handling reduces accidents caused by manual lifting.

Simply put, elevators allow businesses to streamline workflows, reduce costs, and scale production seamlessly.

Types of Bucket Elevators

Not all bucket elevators are the same. Different industries have unique requirements, which is why multiple types of bucket elevators exist. Here are the most common ones:

1. Centrifugal Discharge Bucket Elevators

These are designed to handle free-flowing materials like grains or sugar. The buckets scoop material from the boot section and fling it out at high speeds into the discharge chute.

2. Continuous Discharge Bucket Elevators

These elevators gently discharge material without breaking fragile items like seeds, food pellets, or glass. They are ideal for handling delicate materials that require careful processing.

3. Positive Discharge Bucket Elevators

Designed with pivoted buckets, these elevators handle sticky or sluggish materials that may not flow freely. They ensure complete discharge of the load.

4. Z-Type or C-Type Bucket Elevators

Specially designed for flexible layouts, these elevators move materials in multiple directions (vertical and horizontal). They are widely used in food packaging and processing lines.

Key Components of a Bucket Elevator

To fully understand how a bucket elevator works, let’s break down its core components:

- Buckets: The containers that hold and transport the material.

- Belts or Chains: The mechanism that connects the buckets and drives their movement.

- Head Section: The top of the elevator where materials are discharged.

- Boot Section: The bottom where buckets scoop material.

- Casing: The enclosure that protects and supports the moving parts.

- Motor and Drive System: Provide the power to operate the elevator.

Each of these components works in harmony to ensure smooth operation, durability, and maximum performance.

Applications of Bucket Elevators

Bucket elevators are used across a wide spectrum of industries due to their adaptability and effectiveness. Some common applications include:

- Agriculture: Transporting grains, seeds, and fertilizers.

- Food Industry: Handling powders, snacks, sugar, flour, and rice.

- Pharmaceuticals: Moving delicate powders and capsules.

- Mining and Minerals: Transferring ores, coal, and crushed stones.

- Chemical Industry: Safely transporting powdered chemicals and raw materials.

Advantages of Using a Bucket Elevator

Businesses that adopt bucket elevators enjoy multiple benefits, including:

- High Efficiency: They can move large volumes quickly and continuously.

- Space-Saving Design: Vertical transport saves floor space in crowded facilities.

- Durability: Built from robust materials to withstand harsh conditions.

- Versatility: Capable of handling both fine powders and larger, heavier materials.

- Customization Options: Can be tailored for specific industries and needs.

Maintenance Tips for Bucket Elevators

To keep your bucket elevator performing at its best, regular maintenance is crucial:

- Lubricate chains and moving parts regularly.

- Inspect buckets and belts for wear and tear.

- Clean the casing to prevent material buildup.

- Check alignment of pulleys and sprockets.

- Replace damaged parts promptly to avoid breakdowns.

Choosing the Right Bucket Elevator for Your Business

Not every bucket elevator is suitable for every industry. Here are a few factors to consider when selecting one:

- Material characteristics (free-flowing, sticky, fragile, etc.)

- Required capacity (tons per hour)

- Space availability (height and floor layout)

- Discharge method (centrifugal, continuous, or positive)

- Budget and customization options

Why Choose The Packaging Edge?

At The Packaging Edge, we go beyond simply providing machines. We partner with businesses to enhance their efficiency and productivity. Here’s why businesses trust us for elevator solutions:

- Industry Expertise: Years of experience in packaging and material handling.

- Tailored Solutions: We recommend equipment based on your specific requirements.

- Quality Assurance: Our machines are built for durability and reliability.

- After-Sales Support: From installation to maintenance, we’ve got you covered.

Future of Bucket Elevators: Automation and Innovation

With the rise of Industry 4.0 and smart manufacturing, elevators are evolving too. Modern systems now integrate:

- Automation for precise control and minimal human intervention.

- Sensors to detect wear, load, and efficiency.

- IoT connectivity for real-time monitoring and predictive maintenance.

Final Thoughts

A bucket elevator is more than just a machine—it’s a critical link in your production chain. Whether you’re in food processing, agriculture, mining, or pharmaceuticals, the right bucket elevator can dramatically improve your material handling process, reduce costs, and enhance safety. At The Packaging Edge, we are dedicated to helping businesses harness the power of elevators for long-term success.

If you’re ready to take your material handling operations to the next level with a reliable and efficient bucket elevator, reach out to The Packaging Edge today. Our team of experts will guide you in selecting the right equipment tailored to your unique business needs.

Contact us now at: 📧 thepackagingedge@gmail.com

Let’s build efficiency, productivity, and success together!

Related Articles

- Automated Material Handling: Transforming Packaging Operations for Maximum Efficiency

- Spiral Conveyor: The Future of Efficient Material Handling | The Packaging Edge

- Compression Conveyor: The Game-Changer in Modern Packaging – The Packaging Edge

- Roller Conveyor: The Ultimate Guide to Smarter Packaging Solutions

- The Future of Material Handling: Why Modular Conveyors Are Revolutionizing Packaging Operations

- Flat Belt Conveyor: The Essential Guide for Modern Packaging Operations

- Conveying Solutions: Driving Efficiency and Innovation with The Packaging Edge

- Bagging Machine: The Ultimate Guide to Efficiency and Growth in Packaging

- Industrial Conveyor Systems: The Backbone of Modern Manufacturing

- Pouch Case Packer – Boost Efficiency with Automated Packaging Solutions