In today’s fast-paced, highly automated packaging environments, carton erector machines have become indispensable. Whether you’re running a small-scale distribution center or managing a massive e-commerce operation, automating the carton erection process can significantly improve productivity, consistency, and overall efficiency.

But what exactly are carton erector machines? How do they work? And more importantly, how can you choose the right one for your business?

In this comprehensive guide, we’ll cover everything you need to know about carton erector machines, from their basic functionality to the advanced features in modern models. By the end of this post, you’ll be equipped to make an informed decision about integrating this essential machinery into your packaging line.

What is a Carton Erector Machine?

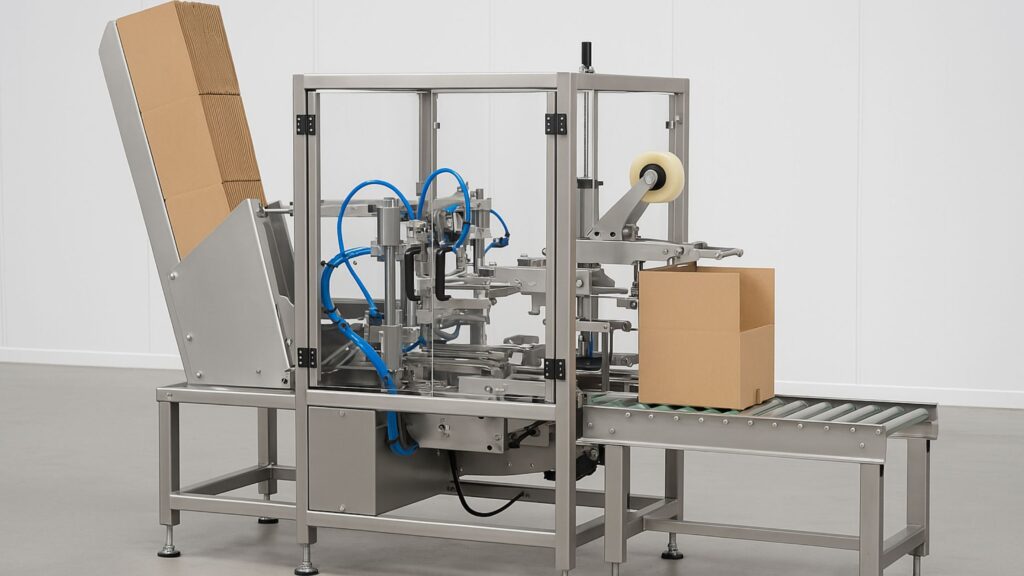

A carton erector machine is a piece of automated equipment designed to take flat-packed cardboard cartons (or boxes), form them into their three-dimensional shape, and seal the bottom flaps using adhesive tape or hot glue. The primary function of this machine is to automate what is traditionally a manual and time-consuming task, enabling businesses to save labor, reduce errors, and speed up production.

These machines are also known as case erectors or box formers. They are typically used in tandem with other packaging equipment, such as case packers, labelers, and sealers, to streamline the packaging process from start to finish.

Why Carton Erector Machines Matter in Modern Packaging

Manual box forming might seem sufficient when you’re only packing a few dozen products a day. But when your output reaches hundreds or thousands of units per hour, manual labor becomes inefficient and costly. Here’s where carton erector machines shine:

1. Speed and Efficiency

Carton erector machines can form and seal dozens of boxes per minute, far outpacing manual labor. This increase in throughput can be the difference between meeting demand or falling behind.

2. Consistency

Manual box forming introduces variability—improper folding, uneven taping, or incomplete sealing. A carton erector ensures each box is uniform and secure.

3. Labor Savings

Reducing manual work means you can redeploy your staff to more critical, value-added tasks. Over time, the investment in automation pays for itself through labor savings.

4. Reduced Waste

Improperly erected boxes lead to damaged products, returns, and wasted materials. Automated carton erectors reduce these risks by ensuring precision in box formation.

How Do Carton Erector Machines Work?

While different models may vary in complexity and design, most carton erector machines follow the same basic steps:

-

Magazine Loading: Flat boxes are loaded into a magazine. The machine draws them in one at a time.

-

Box Forming: Using suction cups or mechanical arms, the flat box is opened into a rectangular shape.

-

Bottom Flap Folding: The bottom flaps of the box are automatically folded in a specific sequence to ensure strength and stability.

-

Sealing: The flaps are sealed using tape (pressure-sensitive adhesive) or hot melt glue, depending on the model.

-

Discharge: The formed box is released onto a conveyor or ready for manual packing.

Some machines also include top flap tucking and sealing, though these are usually combined with case sealers in more advanced setups.

Types of Carton Erector Machines

There are several types of carton erector machines, each suited for different production environments:

1. Semi-Automatic Carton Erectors

-

Require some manual input (typically placing the box in the machine).

-

Ideal for small to mid-volume operations.

-

Lower cost and footprint.

-

Flexible for varied box sizes.

2. Fully Automatic Carton Erectors

-

Entire process is automated: feeding, erecting, sealing, and discharging.

-

High-speed operations—perfect for large-scale packaging lines.

-

Higher upfront cost but significant ROI over time.

-

Advanced features like touch-screen controls, error detection, and size adjustment.

3. Hot Melt Carton Erectors

-

Use hot glue instead of tape for sealing.

-

More secure seal, often used in food, beverage, and pharma industries.

-

Requires glue supply and maintenance but provides aesthetic and strong seals.

4. Custom and Modular Erectors

-

Tailored to specific product lines, box sizes, or material handling systems.

-

Can be integrated into a fully automated warehouse or production line.

Key Features to Look for in Carton Erector Machines

When investing in a carton erector, it’s important to consider more than just price and speed. Here are some key features to evaluate:

1. Box Size Flexibility

Can the machine handle a range of carton sizes? This is critical if your business deals with multiple SKUs.

2. Speed and Output

Measured in boxes per minute (BPM), higher speeds are vital for large operations, but mid-sized businesses can often get by with 10–15 BPM.

3. Footprint

Space constraints matter. Look for compact models if you’re operating in a smaller warehouse.

4. Sealing Options

Do you need tape or glue? Hot melt glue is faster and stronger but requires more upkeep.

5. Changeover Time

How long does it take to switch between box sizes? Look for tools-free adjustment or automated changeover features.

6. Build Quality

Stainless steel or powder-coated frames are more durable and easier to clean—especially important in food-grade environments.

7. Safety Features

Emergency stop buttons, protective guards, and sensors should be standard.

Industries That Benefit from Carton Erector Machines

Carton erector machines are not limited to any one industry. Here are just a few sectors where they have become a vital part of operations:

-

E-Commerce & Fulfillment Centers

-

Food & Beverage

-

Pharmaceutical & Medical Supplies

-

Consumer Electronics

-

Automotive Parts

-

Retail & Wholesale Distribution

Essentially, any business that needs to pack products into boxes at scale can benefit from carton erector automation.

Maintenance and Best Practices

To keep your carton erector running at peak performance, follow these best practices:

-

Routine Inspections – Check belts, suction cups, sensors, and glue nozzles regularly.

-

Training – Train staff thoroughly on operation and basic troubleshooting.

-

Cleaning – Keep sensors and glue/tape heads free from dust and debris.

-

Lubrication – Follow manufacturer guidelines for mechanical parts.

-

Software Updates – If your machine has PLC controls or software, update them periodically.

Regular maintenance prevents downtime and extends the lifespan of your equipment.

The Future of Carton Erector Machines

As Industry 4.0 continues to evolve, carton erector machines are becoming smarter, faster, and more integrated:

-

IoT Connectivity – Real-time monitoring and predictive maintenance.

-

AI-Powered Adjustments – Auto-calibration based on carton type.

-

Energy Efficiency – Lower power consumption and eco-friendly glue systems.

-

Collaborative Robots (Cobots) – Working alongside human operators for greater flexibility.

Smart packaging lines will depend more and more on intelligent erectors to handle a diverse range of products quickly and accurately.

Final Thoughts

In a world where speed, consistency, and cost-efficiency rule, carton erector machines are no longer a luxury—they’re a necessity. They streamline operations, reduce labor costs, and help ensure your products are packaged securely and professionally every single time.

Whether you’re scaling up your business or replacing outdated manual processes, investing in the right carton erector machine can transform your packaging line from a bottleneck into a productivity powerhouse.

Have questions about choosing a carton erector for your business? Drop a comment below or reach out for personalized recommendations. Let’s automate smarter, not harder.

Related Articles

- Powder Packing Machines: Everything You Need to Know

- Case Packer Machines: The Backbone of Modern Packaging Lines

- VFFS Machines: The Backbone of Modern Packaging Solutions

- Case Packers: The Backbone of Modern Packaging Automation

- Blister Packaging Machines: Everything You Need to Know

- Heat Seal Machines: How They Work, Types, Applications, and Buying Tips

- Everything You Need to Know About Cartoning Machines

- Pouch Filling Machines: Types, Benefits, and Industry Applications

- Everything You Need to Know About Coffee Packaging Machines

- The Future of Efficiency: Exploring the World of Automatic Packing Machines