Heat Seal Machines: In the world of packaging and product preservation, heat seal machines play a critical role. These versatile devices are used across industries to create airtight, secure seals that protect products from contamination, spoilage, or damage during transportation and storage. Whether you’re in food packaging, pharmaceuticals, manufacturing, or retail, understanding how heat seal machines work and which type suits your needs can make a significant difference in efficiency and product quality.

This comprehensive guide explores everything you need to know about heat seal machines—from their working mechanism and types to their applications, benefits, and how to choose the right one for your business.

What Is a Heat Seal Machine?

A heat seal machine, also known as a heat sealer, is a device that uses heat and pressure to fuse two materials together, typically plastic or other thermoplastics. The primary goal is to create a seal that is both airtight and watertight, ensuring the integrity of the product inside.

How It Works

Heat seal machines operate on a relatively simple principle: heat + pressure = seal.

-

Heat Application: Heating elements warm up to a specific temperature suitable for melting the plastic material.

-

Pressure: The machine applies pressure to the materials being sealed, pressing them together.

-

Cooling Time: After heating and compression, the seal is allowed to cool for a few seconds, creating a permanent bond.

This process may vary slightly depending on the machine type and materials used, but the basic mechanism remains the same.

Types of Heat Seal Machines

There are several types of heat seal machines, each designed for specific materials and applications. Let’s break down the most common types:

1. Impulse Heat Sealers

Impulse sealers use a short burst of electricity to heat a nichrome wire. Heat is generated only when the machine is in use, which makes them energy-efficient and ideal for sealing thermoplastic materials like polyethylene or polypropylene.

Best For:

-

Low to medium volume packaging

-

Poly bags, plastic films

Pros:

-

Energy-efficient

-

Precise control

-

Cool to the touch when not in use

2. Constant Heat Sealers

These machines maintain a continuously heated sealing bar. They are suitable for thicker materials and laminates that require consistent heat.

Best For:

-

Foil bags

-

Cellophane

-

Coated films

Pros:

-

Ideal for heavy-duty sealing

-

Stronger seals

-

Reliable for thicker materials

Cons:

-

Always hot, may pose a safety risk

-

Higher energy consumption

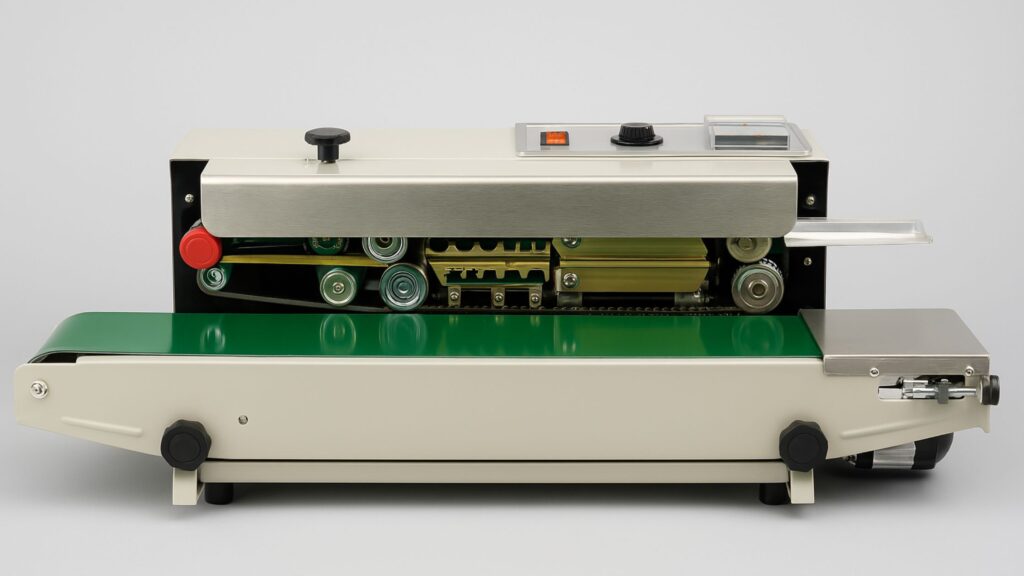

3. Band Sealers (Continuous Sealers)

Band sealers are continuous sealers that move bags through heated jaws via a conveyor belt. They are perfect for high-volume operations.

Best For:

-

Production lines

-

Pre-filled pouches

-

Medium to large packaging runs

Pros:

-

High-speed sealing

-

Adjustable temperature and speed

-

Great for consistent and automated sealing

4. Vacuum Sealers with Heat Sealing

These machines not only seal the bag but also remove air, extending shelf life. Common in food and medical packaging.

Best For:

-

Perishable food items

-

Medical equipment

-

Electronics

Pros:

-

Increases product longevity

-

Combines vacuum and heat seal

-

Strong, tamper-evident seals

Applications of Heat Seal Machines

Heat seal machines are used in an array of industries, with each application tailored to the specific packaging requirements of the product.

1. Food Industry

Perhaps the most widespread use of heat seal machines is in food packaging. From snack bags to vacuum-sealed meats, these machines help prevent contamination and extend shelf life.

Common Uses:

-

Sealing plastic bags for chips, frozen foods

-

Vacuum-sealing meat, cheese, and produce

-

Creating tamper-proof packaging

2. Pharmaceutical and Medical

Heat sealers are critical in maintaining sterile conditions for medicines, surgical tools, and diagnostic kits.

Common Uses:

-

Sealing blister packs

-

Medical pouch sealing

-

Sterile packaging for surgical instruments

3. Retail Packaging

Retailers use heat sealers to present products in clean, sealed formats—think of hanging plastic packages or shrink-wrapped goods.

Common Uses:

-

Clothing bags

-

Electronic accessories

-

Toys and small tools

4. Industrial and Manufacturing

Industries often use heat sealers for heavy-duty tasks like packaging automotive parts, chemicals, or construction materials.

Common Uses:

-

Bulk packaging

-

Protective wraps

-

Corrosion-resistant packaging

Benefits of Using Heat Seal Machines

Investing in a high-quality heat seal machine offers numerous advantages:

1. Improved Product Shelf Life

By creating airtight and watertight seals, products are protected from moisture, oxygen, and contaminants.

2. Professional Packaging

A uniform, clean seal enhances the appearance and credibility of the product, especially in retail settings.

3. Tamper Evident

A good heat seal is difficult to tamper with without noticeable damage, providing security for consumers.

4. Reduced Waste

Sealed packaging helps prevent spoilage and leaks, cutting down on product loss and waste.

5. Cost-Effective

Automated or semi-automated heat seal machines reduce labor costs and increase productivity over manual methods.

Key Factors to Consider When Buying a Heat Seal Machine

Choosing the right heat seal machine depends on your packaging needs, materials, and budget. Here are the top things to evaluate:

1. Material Compatibility

Not all heat sealers are compatible with every plastic or film. Make sure the machine works with the material you’re sealing (e.g., PE, PP, Mylar, foil).

2. Sealing Width

Choose a machine with a sealing width that suits your package size. Wider seals are more durable and leak-resistant.

3. Seal Strength

Check the seal strength specifications, especially if packaging liquids or heavy items.

4. Volume Requirements

High-volume operations will benefit from continuous band sealers or automatic heat sealers. For low-volume businesses, impulse sealers may be sufficient.

5. Temperature Control

Accurate temperature settings ensure quality seals without burning or under-sealing materials.

6. Safety Features

Look for features like heat-resistant handles, automatic shut-off, and emergency stop buttons to minimize risk.

7. Budget

Prices range widely—from $50 for basic manual models to several thousand dollars for industrial sealers. Balance cost with long-term ROI.

Maintenance and Troubleshooting Tips

Proper maintenance of your heat seal machine extends its life and ensures consistent performance.

Routine Maintenance

-

Clean the sealing bar regularly to prevent buildup.

-

Replace worn-out Teflon strips and heating elements as needed.

-

Check wiring and electrical components for wear or damage.

-

Lubricate moving parts according to the manufacturer’s instructions.

Common Issues and Fixes

| Problem | Possible Cause | Solution |

|---|---|---|

| Inconsistent seal | Uneven heat distribution | Check heating elements, recalibrate temperature |

| Bag not sealing completely | Insufficient pressure | Adjust pressure settings |

| Burnt or melted bags | Too high temperature | Lower heat settings |

| Machine not powering on | Electrical fault | Check fuse, wiring, and switch |

Conclusion: Heat Seal Machines

Heat seal machines are indispensable tools in today’s packaging and manufacturing landscape. Whether you’re sealing snack bags or sterilizing medical tools, the right heat sealer improves efficiency, product safety, and customer satisfaction.

Before purchasing, evaluate your product type, packaging volume, and material needs. Whether you’re a small business just starting or a large manufacturer scaling operations, there’s a heat seal machine out there tailored to your specific requirements.

By investing in a quality heat sealer and maintaining it well, you’ll ensure consistent results and a professional finish every time.

If you’d like help choosing the best heat seal machine for your specific needs or industry, feel free to drop a question below or contact our packaging solutions team for expert guidance.

Related Articles

- Everything You Need to Know About Cartoning Machines

- Pouch Filling Machines: Types, Benefits, and Industry Applications

- Everything You Need to Know About Coffee Packaging Machines

- The Future of Efficiency: Exploring the World of Automatic Packing Machines

- Blister Packing Machines: How They Work, Types, Benefits, and Industry Applications

- Flow Wrap Machines: How They Work, Benefits, and Why Your Business Needs One

- Pouch Packing Machines: Types, Benefits, and Buying Tips

- The Evolution and Importance of Food Packaging Machines in Modern Industry

- Vacuum Packaging Machines: What They Are, How They Work, and Why You Need One

- Bubble Wrap Machines: The Ultimate Guide to Protective Packaging Solutions