In the modern era of fast-moving consumer goods and evolving packaging solutions, pouch packing machines have become essential for manufacturers across a wide range of industries. From food and beverages to pharmaceuticals and chemicals, these machines provide efficiency, precision, and consistency in packaging processes. In this in-depth guide, we’ll explore everything you need to know about pouch packing machines—including their types, advantages, applications, and key considerations before making a purchase.

What Are Pouch Packing Machines?

Pouch packing machines are automated systems designed to fill and seal products into pouches or sachets. These machines are widely used in industries that require convenient, flexible, and attractive packaging solutions. Depending on the type of machine, pouch packing systems can handle liquids, powders, granules, pastes, and even solid items.

Pouch packaging offers numerous advantages over traditional packaging methods. It is lightweight, cost-effective, eco-friendly, and provides an excellent surface for branding and labeling.

Types of Pouch Packing Machines

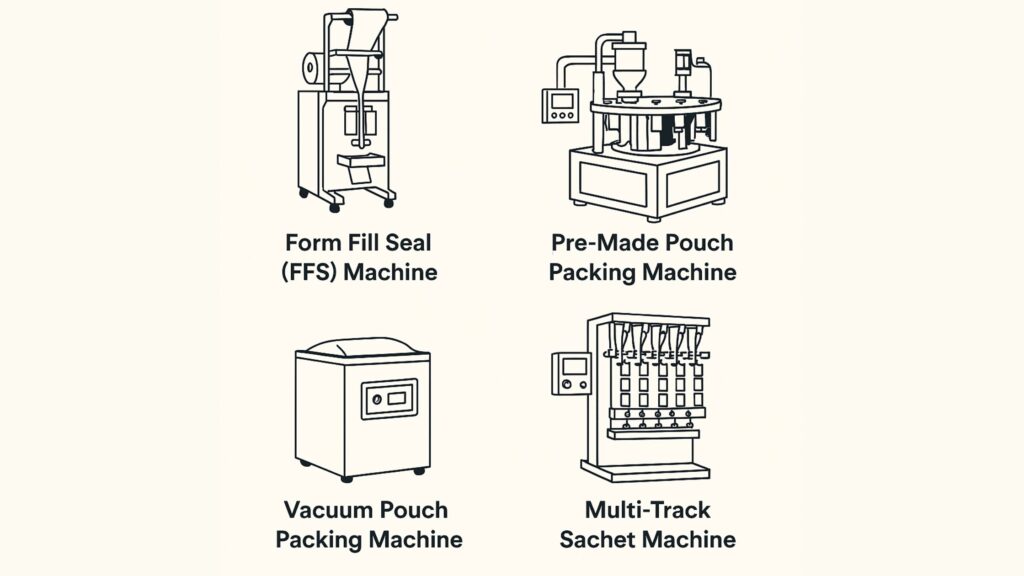

There are various types of pouch packing machines, each tailored to specific product types and production needs. Let’s break down the most common ones:

1. Form Fill Seal (FFS) Machines

FFS machines are highly versatile and commonly used in the packaging industry. They form the pouch from a roll of film, fill the product, and seal the pouch—all in one continuous process.

-

Vertical Form Fill Seal (VFFS) machines: Best for free-flowing products like powders and granules.

-

Horizontal Form Fill Seal (HFFS) machines: Ideal for items that need to be placed horizontally, such as solid products or ready-to-eat meals.

2. Pre-Made Pouch Packing Machines

These machines use pre-fabricated pouches, making them suitable for businesses that prioritize pouch aesthetics and brand consistency. They are excellent for products like coffee, pet food, snacks, and pharmaceuticals.

-

Rotary pouch machines: These are compact, reliable, and ideal for moderate to high production.

-

Linear pouch machines: Better suited for larger operations and high-volume production.

3. Vacuum Pouch Packing Machines

Designed for products that require extended shelf life, these machines remove air from the pouch before sealing. They’re commonly used in the food industry for items like meats, cheese, and pickles.

4. Multi-Track Sachet Machines

These are specialized pouch packing machines designed for mass production of small pouches or sachets. They’re typically used in the pharmaceutical and FMCG sectors for packaging tablets, powders, and liquids in unit doses.

Key Features of Modern Pouch Packing Machines

Modern pouch packing machines are equipped with advanced features that enhance efficiency, minimize waste, and ensure product safety. Here are some standard features:

-

PLC control systems for precision and automation

-

Touchscreen HMI for easy operation and diagnostics

-

Servo motors for accurate filling and sealing

-

Nitrogen flushing for extended product shelf life

-

Photoelectric sensors for precise cutting and sealing

-

Automatic error detection and rejection systems

Advantages of Using Pouch Packing Machines

Investing in a pouch packing machine can transform your production process. Here are the top benefits:

1. Increased Efficiency and Productivity

Manual packaging can be slow and prone to errors. Pouch packing machines automate the entire process, significantly increasing speed and throughput while reducing labor costs.

2. Consistent Quality and Sealing

These machines ensure that every pouch is filled and sealed uniformly. Consistent sealing is crucial for product freshness, safety, and customer satisfaction.

3. Reduced Material Waste

With precise cutting and filling, pouch packing machines help minimize packaging material waste—translating into long-term cost savings.

4. Flexibility Across Products

Whether you’re packaging liquids, powders, or solids, there’s a pouch packing machine that fits your product. Most machines can be adapted to different pouch sizes and types with minor adjustments.

5. Enhanced Product Shelf Life

Vacuum sealing, nitrogen flushing, and airtight packaging help extend the shelf life of perishable products. This is especially valuable in the food, dairy, and pharmaceutical sectors.

Industries That Rely on Pouch Packing Machines

Pouch packing machines are used across a broad spectrum of industries. Some of the most common include:

-

Food and Beverage: Packaging spices, sauces, juices, snacks, and frozen foods.

-

Pharmaceuticals: Sachets for tablets, powders, and medicinal liquids.

-

Cosmetics: Creams, lotions, and sample-size products.

-

Agriculture: Seeds, fertilizers, and pesticides.

-

Pet Food: Single-serve and multi-serve pet food pouches.

-

Detergents and Chemicals: Liquid soaps, cleaning powders, and gel-based products.

What to Consider Before Buying a Pouch Packing Machine

Choosing the right pouch packing machine requires careful consideration. Here are some key factors to guide your decision:

1. Type of Product

Consider the nature of your product—liquid, solid, powder, or granular. Different machines are optimized for different materials.

2. Pouch Style and Material

Are you using stand-up pouches, flat pouches, zip-locks, or spout pouches? Make sure the machine is compatible with your desired packaging format and material (laminate, foil, paper, etc.).

3. Production Volume

Estimate your daily, weekly, or monthly production output. High-speed machines are suitable for large-scale operations, while small or medium businesses may prefer more compact and affordable options.

4. Automation Level

Machines range from semi-automatic to fully automatic. Full automation is ideal for high efficiency but comes at a higher initial investment.

5. Machine Footprint

Check the available space in your facility. Some machines require significant floor space and maintenance access areas.

6. Budget and ROI

Pouch packing machines vary in price depending on their capabilities. Consider the long-term return on investment, including labor savings, reduced waste, and increased output.

Trends in Pouch Packing Technology

The packaging industry is rapidly evolving, and pouch packing machines are not far behind. Here are some of the latest trends shaping the future:

-

Sustainability: Machines that handle recyclable or biodegradable films are gaining popularity.

-

Smart Packaging: Integration of QR codes, RFID tags, and tracking solutions is becoming standard.

-

IoT Integration: Smart machines offer real-time data monitoring and predictive maintenance features.

-

Customization: Modular machines allow for quick changes in pouch size, design, and filling systems.

Final Thoughts

Whether you’re a startup or an established manufacturer, investing in a high-quality pouch packing machine can revolutionize your packaging line. With improved efficiency, better product presentation, and increased customer satisfaction, the right machine can be a game-changer for your business.

When choosing a pouch packing machine, always prioritize quality, support, and long-term adaptability. By understanding your product needs and production goals, you can make an informed choice that delivers maximum value.

As the demand for flexible packaging continues to grow, pouch packing machines are poised to become an indispensable asset in every production facility.

Are you planning to invest in a pouch packing machine? Let us know your product type and production goals, and we can help you choose the perfect solution.

Related Articles

- The Evolution and Importance of Food Packaging Machines in Modern Industry

- Vacuum Packaging Machines: What They Are, How They Work, and Why You Need One

- Bubble Wrap Machines: The Ultimate Guide to Protective Packaging Solutions

- Pallet Shrink Wrap Machines: The Ultimate Guide to Efficient Packaging

- Shrink Wrapping Machines: Types, Benefits, and Applications

- Pallet Wrap Machines: The Ultimate Guide to Efficient Load Securing

- Case Erectors: Streamlining Packaging Operations for Efficiency and Growth

- Vacuum Pack Machines: Benefits, Types, and How to Choose the Best One

- Stretch Wrap Machines: Benefits, Types, and How to Choose the Right One

- The Ultimate Guide to Packaging Machines: Types, Benefits, and Applications