Primary Packaging of Noodles: In the fast-paced world of convenience foods, instant noodles have emerged as a global favorite, satisfying appetites with speed and flavor. Behind the scenes of every satisfying slurp is an often-overlooked hero: the primary packaging of noodles. This essential component plays a pivotal role not only in maintaining freshness and extending shelf life but also in communicating brand identity and consumer appeal.

In this blog post, we explore the intricacies of the primary packaging of noodles, from the materials used and the science behind the packaging to trends and innovations reshaping the industry.

What Is Primary Packaging?

Before delving into noodles specifically, let’s clarify what primary packaging means.

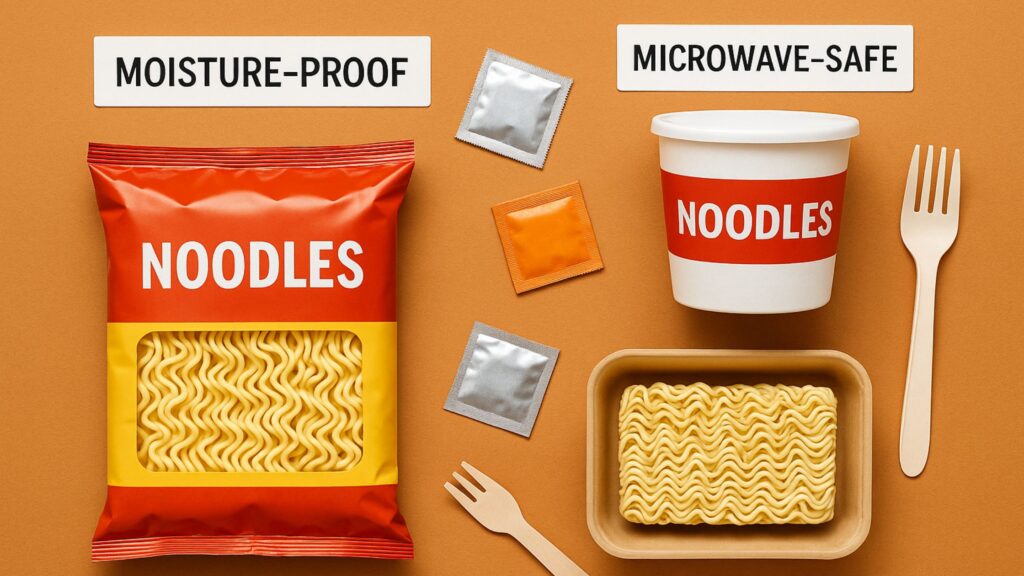

Primary packaging refers to the first layer of packaging that directly encloses the product. In the case of noodles, this could be the plastic film pouch, plastic cup, or molded tray that contains the dry noodle cake and flavor sachets. This packaging serves both functional and aesthetic purposes, including:

-

Protecting the product from physical, chemical, and microbial damage

-

Providing convenience for handling and usage

-

Displaying branding, nutritional information, and cooking instructions

-

Enhancing shelf life

Why Primary Packaging Matters for Noodles

The primary packaging of noodles is crucial for several reasons:

1. Product Protection

Dry noodles are susceptible to moisture, air, light, and physical breakage. If the packaging fails, the product can become stale, moldy, or broken, leading to consumer dissatisfaction and waste.

2. Shelf Life Enhancement

High-quality primary packaging can significantly extend the shelf life of noodles by keeping them free from oxygen and moisture. Oxygen absorbers and vacuum sealing are sometimes used for premium brands.

3. Consumer Convenience

Modern packaging is designed for ease of use. Single-serve cups and microwave-safe bowls have transformed how consumers interact with noodle products.

4. Branding and Marketing

Since the primary packaging is the first thing a consumer sees, it plays a vital role in attracting attention and communicating value. Bold colors, creative fonts, and culturally relevant images are common strategies.

Common Types of Primary Packaging for Noodles

There are three primary forms of packaging used in the noodle industry:

1. Flexible Plastic Pouches

Applications: Instant noodles in brick or cake form

Materials: Multi-layered films made from Polypropylene (PP), Polyethylene (PE), and sometimes metalized films for barrier properties

Advantages:

-

Lightweight and cost-effective

-

Good moisture and gas barrier

-

Printable surface for branding

-

Easy to store and transport

Challenges:

-

Not microwaveable

-

Often not recyclable (due to multilayer composition)

2. Plastic Cups and Bowls

Applications: Ready-to-eat noodles

Materials: Polystyrene (PS), Polypropylene (PP), or Paper-based cups with a plastic lining

Advantages:

-

Heat-resistant and microwave-safe

-

Good for liquid contents like broth

-

Portable and convenient

Challenges:

-

Higher production cost

-

Environmental impact (especially with PS)

3. Paper-based Wrappers and Trays

Applications: Premium or eco-friendly noodle products

Materials: Coated or laminated paperboard, often with biodegradable linings

Advantages:

-

More sustainable

-

Printable and customizable

-

Consumer appeal due to eco-friendliness

Challenges:

-

May require additional barrier layers for moisture resistance

-

Less durable than plastic in humid conditions

Packaging Components Beyond the Noodle Cake

The primary packaging of noodles often includes more than just the noodles. Common additional components include:

1. Seasoning Sachets

Small pouches for flavor powders, oils, or dehydrated vegetables, usually made of aluminum foil laminates or plastic films. These must be airtight to prevent clumping and rancidity.

2. Forks or Chopsticks

Many cup noodles include disposable utensils made of plastic or biodegradable materials for convenience.

3. Lids or Seals

Cups or bowls typically feature foil seals and plastic or paperboard lids. These must be tamper-evident and hermetically sealed for hygiene.

Material Science Behind Noodle Packaging

1. Multilayer Films

To achieve the right balance of strength, barrier properties, and printability, packaging films often consist of multiple layers:

-

Outer Layer: Printable layer, usually BOPP (Biaxially Oriented Polypropylene)

-

Middle Layer: Barrier layer, such as metallized PET or EVOH (Ethylene Vinyl Alcohol)

-

Inner Layer: Heat-sealable layer like LDPE (Low-Density Polyethylene)

2. Barrier Properties

Good noodle packaging must block:

-

Moisture: to prevent softening and spoilage

-

Oxygen: to reduce oxidation of oils in flavor sachets

-

Light: especially UV, which can degrade flavor and color

Regulatory Considerations

Noodle packaging must comply with food safety regulations, such as:

-

FDA (U.S.)

-

EFSA (Europe)

-

FSSAI (India)

-

ISO 22000 for food safety management

These regulations dictate the use of food-grade materials, proper labeling, and shelf-life declarations.

Sustainability in Noodle Packaging

As environmental awareness grows, the industry is under pressure to make the primary packaging of noodles more sustainable.

1. Biodegradable Films

Manufacturers are exploring films made from PLA (Polylactic Acid) or starch-based materials, which decompose faster than petroleum-based plastics.

2. Recyclable Laminates

Mono-material laminates made entirely of PP or PE are being developed to replace multilayer films that are difficult to recycle.

3. Reduced Packaging

Some brands are redesigning their packaging to use less material overall, reducing carbon footprints and costs.

4. Paper-Based Alternatives

Brands like Nissin and Cup Noodles have introduced paper-based cups and wraps to appeal to eco-conscious consumers.

Innovations in Noodle Packaging

The noodle packaging industry is ripe with innovation. Some of the latest trends include:

1. Smart Packaging

Embedded QR codes that provide cooking tutorials, nutrition facts, or augmented reality experiences.

2. Microwavable Innovations

Materials that can withstand high temperatures without warping or leaching, enabling microwave-ready packaging.

3. Tamper-Proof Seals

Advanced sealing technology that ensures product integrity and improves consumer trust.

4. Anti-Counterfeit Features

Holograms, RFID tags, or special inks to fight product duplication in markets where counterfeit noodles are a concern.

Case Studies: Leading Brands and Their Packaging Strategies

1. Maggi (Nestlé)

Maggi uses multi-layered plastic pouches for their classic instant noodles and paper-based cups for premium ranges. Their branding is bright and immediately recognizable.

2. Nissin Foods

A pioneer in noodle cups, Nissin has been testing recyclable paper-based cups and biodegradable lids, leading the shift toward eco-packaging.

3. Indomie

Popular in Africa and Southeast Asia, Indomie’s packaging focuses on vibrant visuals and durability, often including multiple sachets inside.

Challenges in Noodle Packaging

While many advancements have been made, manufacturers still face challenges:

-

Balancing cost and sustainability

-

Meeting diverse global regulations

-

Ensuring shelf stability in tropical climates

-

Reducing packaging waste while maintaining convenience

The Future of Primary Packaging for Noodles

Looking forward, the primary packaging of noodles is likely to become:

-

Smarter – with interactive features and supply chain tracking

-

Greener – with fully recyclable or compostable options

-

Minimalist – as brands reduce packaging size and weight

-

Personalized – using digital printing to offer limited editions and customized visuals

Conclusion: Primary Packaging of Noodles

The primary packaging of noodles is a vital yet underappreciated part of the noodle industry. It goes far beyond just holding the product—packaging protects, preserves, markets, and even enhances the user experience. With increasing demand for sustainability, safety, and smart features, this aspect of food manufacturing is undergoing a fascinating transformation.

As manufacturers, consumers, and regulators push for innovation, the noodle wrapper or cup we once took for granted may soon become a marvel of food technology.

Related Articles

- Primary Packaging of Milk: Materials, Methods, and Innovations

- Primary Packaging of Maggi Noodles: A Deep Dive into Safety, Design, and Sustainability

- Primary Packaging of Lipstick: A Deep Dive into Design, Function, and Innovation

- Primary Packaging of Ice Cream: A Comprehensive Guide

- Primary Packaging of Colgate Toothpaste: Materials, Functions & Innovations

- Primary Packaging of Clothes: Everything You Need to Know

- Primary Packaging of Cadbury Dairy Milk: A Sweet Blend of Functionality and Branding

- Primary Packaging of Biscuits: Materials, Functions, and Evolving Trends

- Understanding Primary Secondary Tertiary Packaging: A Comprehensive Guide

- Primary Packaging in Pharmaceutical Industry: Types, Importance, and Trends