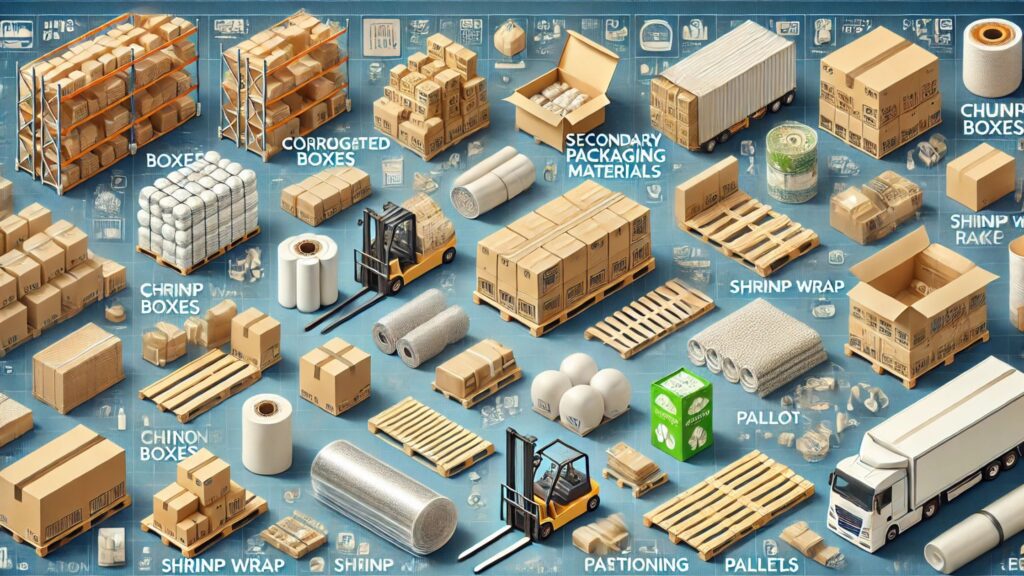

When it comes to packaging, most people think of the primary layer that directly encloses a product. However, secondary packaging material plays an equally vital role in protecting, transporting, and marketing products efficiently. In this article, we will explore the significance of secondary packaging material, its types, and how businesses can optimize its use for sustainability and cost-effectiveness.

What is Secondary Packaging Material?

Secondary packaging material refers to the packaging that holds and groups primary packages together. Unlike primary packaging, which comes into direct contact with the product, secondary packaging provides additional protection and facilitates bulk handling. It is essential for product branding, safety, and logistics.

Types of Secondary Packaging Material

- Corrugated Boxes – These sturdy cardboard boxes are widely used for transporting goods in bulk. They provide durability and cushioning to prevent damage during transit.

- Shrink Wrap and Stretch Wrap – Plastic wraps are commonly used to bundle products together, ensuring they remain intact during shipping and storage.

- Cartons and Trays – Used in industries such as food, beverage, and pharmaceuticals, these help in easy handling and display of products.

- Pallets and Crates – Made from wood, plastic, or metal, these materials support large shipments and facilitate smooth transportation.

- Paperboard and Fiberboard Packaging – Lightweight and recyclable, these materials are a sustainable choice for various industries.

- Foam Inserts and Cushioning Materials – Used to protect fragile items like electronics and glassware from shocks and impacts.

Why is Secondary Packaging Material Important?

- Protection and Durability – It safeguards products from physical damage, contamination, and environmental factors such as moisture and dust.

- Efficient Logistics – Secondary packaging material helps optimize space utilization, making shipping and storage more efficient.

- Branding and Marketing – Custom-designed secondary packaging enhances brand visibility and attracts customers.

- Sustainability – With eco-friendly packaging options, businesses can reduce their carbon footprint and appeal to environmentally conscious consumers.

- Regulatory Compliance – Certain industries require secondary packaging to meet specific safety and hygiene standards.

Best Practices for Sustainable Secondary Packaging

- Use Recyclable Materials – Opt for paper-based or biodegradable packaging instead of plastic.

- Reduce Packaging Waste – Minimize excess packaging to decrease material usage and costs.

- Implement Lightweight Packaging – Lighter materials reduce transportation costs and environmental impact.

- Encourage Reuse and Recycling – Design packaging that customers can repurpose or recycle easily.

- Leverage Smart Packaging Technologies – Utilize QR codes or RFID tags for tracking and reducing packaging inefficiencies.

Conclusion

Secondary packaging material is more than just an outer layer—it plays a crucial role in ensuring product safety, efficient logistics, and enhanced branding. By choosing sustainable materials and innovative designs, businesses can improve efficiency while contributing to environmental conservation. Investing in high-quality secondary packaging material is not just a necessity but a strategic move toward a more sustainable and cost-effective supply chain.

Related Articles

- The Art and Science of Packaging | Trends, History & Future

- Secondary Packaging Examples: Enhancing Protection and Presentation

- Primary and Secondary Packaging: Understanding Their Roles and Importance

- The Importance of Secondary Packaging Machinery in Modern Manufacturing

- Secondary Packaging in Pharmaceutical Industry: Importance & Innovations

- What Is Secondary Packaging? The Essential Guide for Businesses

- The Ultimate Guide to Popcorn Packaging: Innovation, Trends, and Sustainability

- The Art and Science of Honey Packaging: A Guide to Preserving Nature’s Sweetness

- The Future of Takeaway Packaging: Sustainable and Innovative Solutions

- What Is Primary Packaging? A Complete Guide