In the world of modern packaging, flow pack machines have emerged as a game-changing solution for businesses seeking efficiency, precision, and scalability. Whether you’re packaging food, pharmaceuticals, cosmetics, or industrial parts, these machines deliver high-speed performance and reliable protection. This comprehensive guide explores everything you need to know about flow pack machines—from how they work, their benefits, applications across industries, to the latest innovations shaping the market.

What Are Flow Pack Machines?

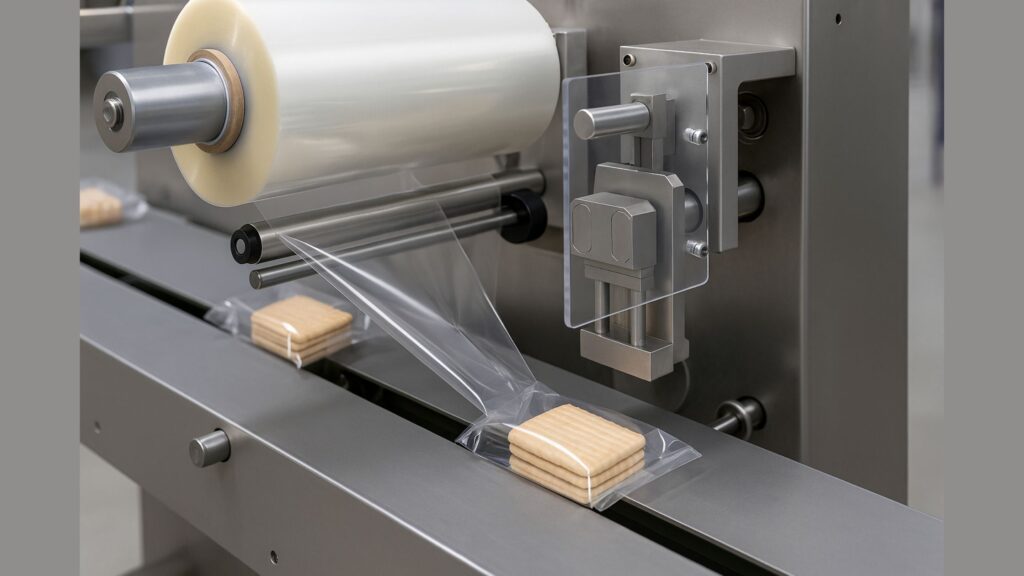

Flow pack machines, also known as horizontal form-fill-seal (HFFS) machines, are automated systems used to wrap products in a flexible film. These machines form a package around the product, seal it on three sides (top, bottom, and back), and then cut it into individual units.

The process is continuous and horizontal—products are fed into the machine in a single line, wrapped with film, and sealed as they move forward. This seamless motion allows for high-speed packaging with minimal product handling.

How Flow Pack Machines Work

Understanding the mechanism of flow pack machines can help businesses optimize operations and choose the right model for their needs. Here’s a step-by-step breakdown of how these machines typically work:

-

Film Unwinding

The packaging film (typically plastic or foil) is unwound from a roll. The film can be pre-printed with branding, nutritional info, or barcodes. -

Forming the Film Tube

The film is shaped into a tube using a forming box or collar. The product is then inserted into the tube from behind or above. -

Sealing the Back Seam

A longitudinal seal is applied to close the back of the package, forming a continuous film tube with the product inside. -

Creating End Seals

As the tube advances, heated jaws seal the front and back ends of each individual package. -

Cutting the Pack

A knife or rotary cutter separates the sealed units, producing individual flow-wrapped products. -

Discharge and Collection

Finished products are ejected onto a conveyor for further handling—boxing, cartoning, or direct delivery.

Benefits of Flow Pack Machines

Businesses that invest in flow pack machines enjoy a host of advantages:

1. High Speed and Efficiency

Flow pack machines are capable of wrapping hundreds of units per minute, making them ideal for large-scale production environments. Their continuous motion design reduces downtime and boosts overall throughput.

2. Versatility

These machines can handle a wide variety of products—solid, semi-solid, or irregularly shaped items. Whether you’re packaging cookies, medical devices, or auto parts, flow pack machines can be customized to suit your needs.

3. Cost-Effective

Flow wrapping uses less material than other packaging methods. The thin, flexible film reduces costs, and the automation lowers labor expenses.

4. Product Protection

Flow-wrapped products are sealed in an airtight environment, protecting them from contaminants, moisture, and oxidation. This extends shelf life, especially for perishable items.

5. Aesthetic Appeal

Flow pack machines deliver neat, uniform packaging that enhances brand presentation. With printed films, companies can showcase logos, instructions, and promotional messages clearly.

Applications of Flow Pack Machines

Flow pack machines serve an incredibly diverse range of industries. Let’s explore how they are used across various sectors:

Food Industry

Flow pack machines are a staple in food packaging. Common applications include:

-

Bakery items (bread, croissants, biscuits)

-

Confectionery (chocolates, candy bars)

-

Fresh produce (fruits, vegetables)

-

Dairy products (cheese portions)

-

Frozen goods (nuggets, spring rolls)

These machines ensure hygiene and freshness, meeting strict food safety standards.

Pharmaceutical and Medical Devices

Sterility and precision are critical in this sector. Flow pack machines are used to package:

-

Syringes

-

Bandages

-

Surgical tools

-

Tablets and capsules in blister packs

Medical-grade films and controlled environments make flow pack machines suitable for pharma-grade packaging.

Cosmetics and Personal Care

Flow pack machines help brands create attractive, tamper-evident packaging for:

-

Soap bars

-

Face masks

-

Cosmetic kits

-

Disposable wipes

Customization options allow for high-end finishes and brand alignment.

Industrial and Technical Products

From screws and bearings to gaskets and electronic parts, flow pack machines help in bundling small components securely and efficiently.

E-commerce and Promotional Items

For bulk mailings, giveaways, and online orders, flow packing is an effective way to protect and present promotional materials.

Types of Flow Pack Machines

Depending on your production requirements, there are different types of flow pack machines to consider:

1. Horizontal Flow Wrap Machines

These are the most common, where products are fed horizontally into the machine. Ideal for solid, regular-shaped items.

2. Vertical Flow Wrap Machines

Suited for granular or loose items like snacks or powders. These machines use gravity to fill the packages vertically.

3. Box Motion Machines

Designed for thicker films and more secure seals, often used in meat and frozen food packaging.

4. Rotary Jaw Machines

Offer high-speed performance with rotary seal jaws—great for high-volume environments.

Factors to Consider Before Buying a Flow Pack Machine

When selecting a flow pack machine for your production line, consider the following:

Product Type & Size

Your machine must be compatible with your product’s dimensions, weight, and fragility. Irregular shapes may require custom feeding systems.

Packaging Speed

Determine how many units per minute your business needs to maintain profitability and meet demand.

Type of Film

Some machines are optimized for specific film types, like OPP, BOPP, PE, or laminated structures.

Level of Automation

From semi-automatic to fully automatic lines, choose the degree of automation that suits your workforce and budget.

Changeover Time

If you package multiple products, quick and easy changeovers can significantly boost your line’s flexibility.

After-Sales Support

A good supplier should offer training, spare parts availability, remote troubleshooting, and preventive maintenance packages.

Innovations in Flow Pack Technology

The world of flow pack machines is rapidly evolving. Here are some of the latest trends and technologies:

Smart Sensors and IoT

Sensors can monitor temperature, sealing pressure, film tension, and product positioning. Integrated with the Internet of Things (IoT), these machines enable predictive maintenance and data analysis for better efficiency.

Eco-Friendly Films

With sustainability a key concern, many businesses are switching to recyclable or compostable films. Flow pack machines are being adapted to work with these greener materials without compromising seal integrity.

Robotics Integration

Robotic arms can feed products, remove rejects, or load finished packs into cartons, minimizing manual handling and increasing hygiene.

Modular Designs

Modular flow pack machines allow businesses to add or remove features like printers, coders, or inspection cameras depending on production needs.

Vision Systems

Integrated vision systems can inspect seals, check for missing items, and ensure branding elements are correctly placed.

Case Study: Flow Pack Machines in Action

Let’s look at how a mid-sized bakery improved its packaging process with flow pack machines:

Challenge:

Manual packaging was time-consuming, inconsistent, and couldn’t meet growing demand. The company faced product damage and hygiene issues.

Solution:

They installed a horizontal flow pack machine with a feeding conveyor and automatic film roll changeover. The machine was configured to handle multiple sizes of bread and pastries.

Result:

-

Packaging speed increased from 20 to 120 units/min

-

Product shelf life improved by 30% due to airtight seals

-

Labor costs reduced by 40%

-

Enhanced brand presentation with printed film

This case illustrates how investing in flow pack machines can directly boost productivity, reduce costs, and improve product quality.

Conclusion

Flow pack machines are an essential asset for modern packaging operations. They offer unmatched speed, consistency, and flexibility, serving a wide array of industries. As technology advances and consumer expectations grow, these machines will continue to evolve—adopting smart sensors, sustainable materials, and robotic integration.

Whether you’re a small artisan brand or a large-scale manufacturer, there’s a flow pack solution that fits your needs. If you’re looking to streamline operations, improve product presentation, and ensure long-term cost efficiency, flow pack machines are worth every penny.

Looking to learn more about specific models or get help selecting the right flow pack machine for your business? Let’s talk! Drop a comment or contact us directly for expert advice.

Related Articles

- Sachet Filling Machines: Types, Applications & Buying Guide

- Stick Pack Machines: Revolutionizing Modern Packaging

- Case Erector and Sealer Machines: Boost Efficiency in Your Packaging Line

- Seal Machines: Types, Uses, and How to Choose the Right One

- The Ultimate Guide to Blister Machines: Types, Applications, and Innovations

- Food Packing Machines: Types, Benefits, and Industry Insights

- Skin Packaging Machines: How They Work, Benefits, and Industry Applications

- The Ultimate Guide to Food Packaging Machines for Small Business Owners

- Everything You Need to Know About Carton Sealing Machines: A Comprehensive Guide

- Shrink Tunnel Machines: How They Work, Benefits, and Best Use Cases