When it comes to food packaging, most people think about the materials that come into direct contact with food products—such as plastic wraps, cartons, or cans. However, food secondary packaging plays an equally vital role in protecting food items, ensuring their safe transportation, and maintaining their quality throughout the supply chain.

This article delves into the concept of food secondary packaging, its types, benefits, and why it is essential for modern food businesses.

What is Food Secondary Packaging?

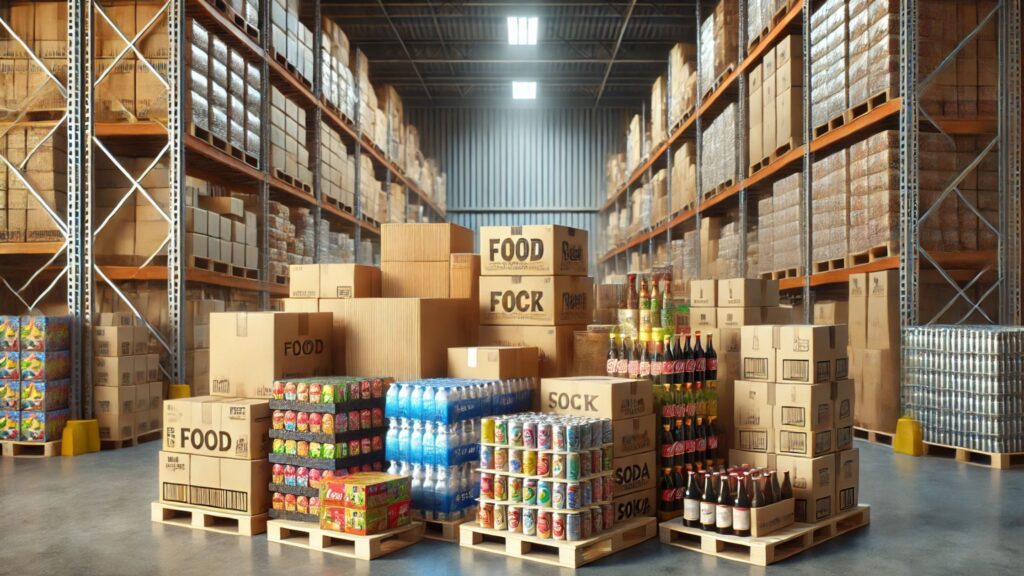

Food secondary packaging refers to the additional layer of packaging that holds multiple units of primary-packaged food products together. Unlike primary packaging, which directly encloses food items (such as a yogurt cup or a chocolate wrapper), secondary packaging does not come into direct contact with the food. Instead, it is designed to provide protection, facilitate storage and transportation, and enhance branding.

Examples of food secondary packaging include:

-

Cardboard boxes used to transport multiple snack bars

-

Shrink wraps bundling soda cans together

-

Corrugated trays holding multiple cartons of milk

-

Plastic crates used for transporting bottles of juice

-

Display-ready packaging for supermarkets and retail stores

This type of packaging is commonly seen in warehouses, supermarkets, and during distribution processes.

Types of Food Secondary Packaging

1. Corrugated Cardboard Boxes

One of the most commonly used materials for food secondary packaging, corrugated cardboard is lightweight, durable, and recyclable. It provides excellent protection against impact, moisture, and temperature changes. These boxes are widely used in the food and beverage industry for bulk packaging.

2. Shrink Wrap and Plastic Films

Shrink wrap is a type of plastic film that tightly encloses multiple products when heat is applied. It is commonly used to bundle water bottles, canned goods, and frozen food products. Shrink wrap helps to maintain product integrity and prevent tampering.

3. Rigid Plastic Crates and Containers

For perishable items such as fruits, vegetables, dairy, and meat products, plastic crates are commonly used. These are reusable and provide ventilation, making them ideal for maintaining the freshness of perishable food items during transportation.

4. Paperboard Cartons

Paperboard cartons are often used for items like eggs, cereal boxes, and frozen meals. They are an environmentally friendly option since they are recyclable and biodegradable.

5. Display-Ready Packaging (Shelf-Ready Packaging)

This type of secondary packaging is designed for easy placement in retail stores. It often comes with perforations or tear-away panels that allow the package to be turned into a display unit on supermarket shelves. Examples include pre-packed snack trays and beverage carriers.

Benefits of Food Secondary Packaging

1. Protection and Safety

Secondary packaging plays a crucial role in protecting food products from external damage, contamination, and environmental factors. It ensures that items remain intact during transportation, reducing the risk of spoilage or breakage.

2. Efficient Transportation and Storage

By grouping multiple units together, food secondary packaging simplifies logistics and storage. It allows manufacturers and retailers to handle large quantities of products efficiently, reducing handling time and costs.

3. Enhanced Branding and Marketing

Secondary packaging often carries branding elements, such as logos, product information, and promotional messages. This helps food brands create a strong visual identity and attract consumers in a competitive market.

4. Sustainability and Waste Reduction

Many businesses are now opting for eco-friendly secondary packaging materials, such as recycled cardboard and biodegradable plastics. Sustainable packaging solutions help reduce waste and carbon footprints, aligning with consumer demand for environmentally responsible practices.

5. Tamper Evidence and Security

Food safety is a critical concern for both consumers and businesses. Secondary packaging often includes tamper-evident features, such as seals and shrink wraps, ensuring that products have not been altered or compromised before reaching the customer.

6. Convenience for Retailers and Consumers

Retailers benefit from secondary packaging that is easy to handle and display. Shelf-ready packaging, for example, minimizes labor costs and speeds up the stocking process. For consumers, packaging that includes resealable or easy-to-carry features enhances convenience.

Trends in Food Secondary Packaging

1. Smart Packaging Technology

Advancements in smart packaging include QR codes, RFID tags, and temperature-sensitive labels that help track food quality and improve supply chain efficiency.

2. Eco-Friendly and Sustainable Materials

With growing concerns over plastic waste, many companies are switching to biodegradable materials, compostable packaging, and recyclable solutions to reduce their environmental impact.

3. Minimalist and Lightweight Packaging

Reducing material use while maintaining durability is a key trend in modern packaging. Companies are exploring thinner but stronger packaging materials to cut costs and promote sustainability.

4. Customization and Personalization

Brands are increasingly using custom-printed secondary packaging to create unique, eye-catching designs that resonate with consumers.

Conclusion

Food secondary packaging may not always get the attention it deserves, but it plays an essential role in ensuring food products remain safe, fresh, and appealing. From protecting goods during transportation to enhancing brand visibility, the right secondary packaging strategy can improve efficiency, reduce costs, and contribute to sustainability.

As consumer preferences and industry regulations evolve, businesses must invest in innovative, eco-friendly, and functional food secondary packaging solutions to stay competitive in the market.

Would you like insights on the best materials for your food packaging needs? Let’s discuss!

Related Articles

- Pharma Secondary Packaging: Importance, Types, and Best Practices

- The Role of Secondary Packaging Equipment in Modern Manufacturing

- Sustainable Secondary Packaging: A Key to Greener Supply Chains

- Kraft Paper Packaging: A Sustainable and Versatile Choice for Businesses

- The Future of Carton Packaging: Sustainability, Innovation, and Market Trends

- Polybag Packaging: Benefits, Uses, and Sustainability

- The Versatility and Importance of Plastic Wrap Packaging

- Shredded Paper for Packaging: A Sustainable and Cost-Effective Solution

- Bubble Packaging: The Ultimate Solution for Protection and Sustainability

- Sandwich Packaging: Ensuring Freshness, Sustainability, and Appeal