In the complex world of logistics, manufacturing, and retail, packaging plays a pivotal role in how products are transported, stored, displayed, and ultimately purchased. While primary packaging—what directly holds the product—is often in the spotlight due to its direct interaction with the consumer, secondary packaging is the crucial middle layer that ensures products arrive in pristine condition and maintain brand identity across supply chains. In this blog post, we’ll explore the multifaceted role of Secondary Packaging, its types, benefits, industry applications, sustainability implications, and best practices for optimization.

What is Secondary Packaging?

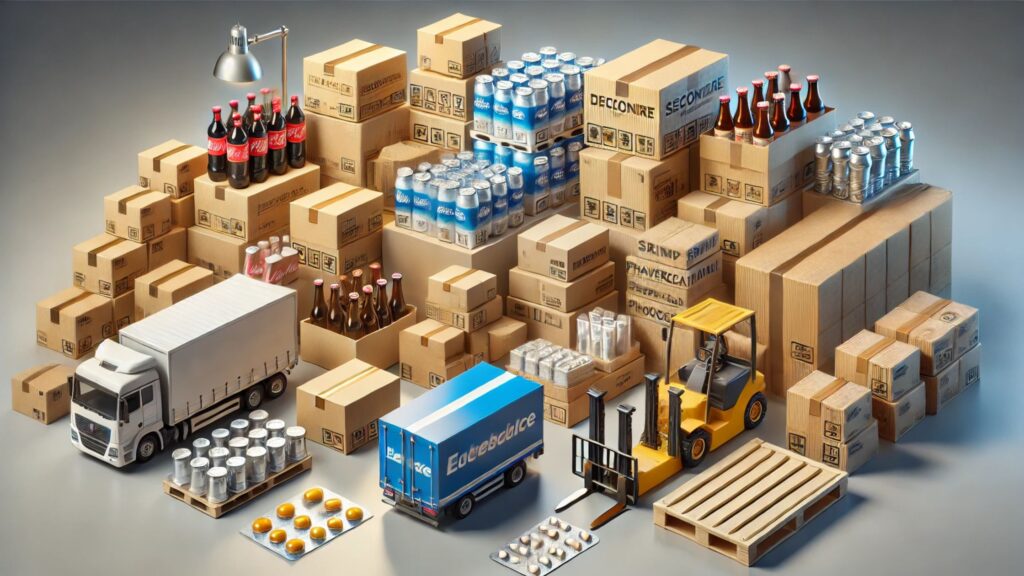

Secondary Packaging is the layer of packaging that groups primary packaged products together for ease of handling, transportation, and storage. It typically does not come in direct contact with the product itself but instead surrounds the primary packaging. Think of it as the bridge between individual consumer-facing packaging and the bulk packaging used for shipping.

Common Examples:

-

Cardboard boxes that hold multiple bottles of shampoo

-

Shrink wraps that bundle cans of soda

-

Retail-ready displays

-

Trays and cartons for product grouping

Secondary packaging serves multiple stakeholders—manufacturers, logistics providers, retailers, and consumers—each relying on its performance for different reasons.

The Functions of Secondary Packaging

To fully appreciate the importance of secondary packaging, let’s break down its core functions:

1. Protection

Secondary packaging plays a critical protective role during storage and transportation. It cushions and supports the primary packaging to prevent breakage, leakage, or other damage caused by mechanical shock, pressure, or environmental conditions.

2. Convenience

Grouping items using secondary packaging simplifies handling and stocking. Whether it’s in a warehouse or a retail shelf, having multiple items in a single unit improves operational efficiency.

3. Branding and Marketing

Though not always consumer-facing, secondary packaging often carries branding elements. Especially in club stores and wholesale retail, it acts as a mobile billboard that reinforces brand presence.

4. Logistical Efficiency

With proper secondary packaging, businesses can optimize space utilization in pallets, trucks, and storage facilities. This results in cost savings and smoother supply chain operations.

5. Regulatory Compliance

For certain industries like pharmaceuticals and food, secondary packaging often carries mandatory information such as batch numbers, expiry dates, and barcodes.

Types of Secondary Packaging

The type of secondary packaging used depends on the product, industry, and distribution method. Here are the most common types:

1. Corrugated Boxes

These are perhaps the most widely used form of secondary packaging. They offer durability, are recyclable, and come in various sizes and strengths.

2. Shrink Wraps

Shrink wrapping bundles products together using a polymer plastic film. When heat is applied, it shrinks tightly over the products, offering visibility and compactness.

3. Plastic Crates and Totes

Reusable and sturdy, these are commonly used in industries where hygiene and strength are critical, such as food and pharmaceuticals.

4. Trays

Paperboard or plastic trays are used to stabilize products, particularly in beverage and dairy sectors.

5. Retail-Ready Packaging (RRP)

Designed for quick shelf display, RRP minimizes handling time and enhances visual merchandising.

Secondary Packaging in Different Industries

Let’s take a closer look at how secondary packaging varies across industries:

1. Food and Beverage

In this sector, secondary packaging must balance protection with presentation. Multipacks, tray and shrink combinations, and branded boxes are common. Temperature and humidity resistance are also important.

2. Pharmaceuticals

Accuracy, traceability, and compliance are crucial. Secondary packaging often includes tamper-evident seals, batch codes, and regulatory markings.

3. Consumer Electronics

Products like smartphones and laptops require rigid secondary packaging with protective cushioning to avoid damage during transit.

4. Retail and E-commerce

With the boom in online shopping, secondary packaging has evolved to handle high volumes, reduce returns due to damage, and offer easy-to-open formats.

5. Automotive

Heavy-duty secondary packaging, such as metal racks or reinforced corrugated boxes, is used to move bulky and sensitive automotive components.

The Role of Secondary Packaging in Sustainability

As environmental concerns grow, secondary packaging is undergoing a transformation to align with sustainability goals. Businesses are now rethinking their packaging strategies to reduce waste, use renewable materials, and improve recyclability.

Sustainable Approaches Include:

-

Lightweighting: Reducing material usage without compromising strength

-

Recyclable Materials: Switching to mono-materials or widely recycled materials like cardboard

-

Reusable Systems: Implementing returnable crates or totes

-

Optimized Design: Using right-sized packaging to reduce air space and improve shipping efficiency

Challenges in Secondary Packaging

Despite its benefits, secondary packaging presents several challenges:

1. Cost Management

Balancing cost with functionality and aesthetics is a constant struggle. Over-packaging adds cost and environmental burden; under-packaging increases the risk of damage.

2. Supply Chain Complexity

Global supply chains add layers of complexity, with different countries having varying packaging regulations and handling requirements.

3. Technological Integration

Embedding RFID tags or smart packaging technologies into secondary packaging requires investment and technical know-how.

4. Customization Needs

Retailers and e-commerce platforms often demand unique secondary packaging solutions, which can strain standardization efforts.

Best Practices for Optimizing Secondary Packaging

To get the most value out of secondary packaging, consider implementing the following best practices:

1. Collaborate Across Departments

Involve logistics, marketing, procurement, and sustainability teams early in the packaging design process.

2. Invest in Packaging Testing

Simulate real-world conditions like vibrations, drops, and compression to ensure your secondary packaging performs under stress.

3. Standardize Where Possible

Standardized packaging sizes and materials simplify logistics, reduce costs, and make recycling easier.

4. Use Digital Tools

Packaging design software and AI can help model load distribution, weight reduction, and space optimization.

5. Monitor KPIs

Track damage rates, return rates, and cost-per-package metrics to continuously improve packaging effectiveness.

Future Trends in Secondary Packaging

The future of Secondary Packaging lies in innovation, digitization, and sustainability. Here are some trends to watch:

1. Smart Packaging

Using sensors and QR codes to track location, temperature, or authenticity.

2. Automation Compatibility

Designing packaging that is compatible with automated packing and sorting systems.

3. Minimalist Aesthetics

As unboxing experiences become more important, brands are seeking sleek and clean secondary packaging.

4. Sustainable Innovation

Materials like mushroom-based foam, paper-based bubble wrap, and biodegradable films are gaining traction.

Final Thoughts

While it may not be the first thing consumers notice, Secondary Packaging is indispensable to modern commerce. From ensuring products arrive safely to enhancing brand recognition and aligning with sustainability goals, secondary packaging is the quiet force behind successful product journeys.

Companies that strategically invest in their secondary packaging solutions not only streamline their operations but also create meaningful environmental and economic impacts. As industries evolve and consumer expectations shift, secondary packaging will continue to play a critical role in shaping the future of packaging and logistics.

Related Articles

- The Art and Science of Packaging | Trends, History & Future

- The Power of Custom Packaging: Elevate Your Brand and Customer Experience

- The Importance of Food Packaging Boxes for Businesses

- Sustainable Packaging: A Step Towards a Greener Future

- Primary Packaging: The First Line of Protection and Branding

- Tertiary Packaging: The Backbone of Efficient Logistics

- The Importance of Protective Packaging in Shipping and Storage

- Flexible Packaging: The Future of Sustainable and Efficient Packaging Solutions

- The Power of Rigid Packaging: A Game-Changer in Product Protection and Branding